Magnetic testing of cemented carbide valve balls mainly focuses on two core indicators: coercivity (Hcj) and magnetic saturation (Ms). Magnetic testing methods…

Magnetic testing of cemented carbide valve balls mainly focuses on two core indicators: coercivity (Hcj) and magnetic saturation (Ms). Magnetic testing methods…

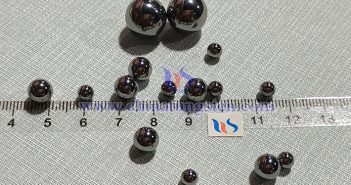

The surface finish of cemented carbide valve balls is one of the key factors affecting their sealing performance. Surface finish directly affects…

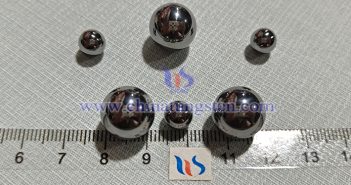

Cemented carbide valve balls are mainly composed of tungsten carbide (WC) hard phase and cobalt (Co) and other binder phases, manufactured using…

The combination of cemented carbide valve balls and stainless steel valve seats is a powerful solution designed to cope with extreme working…

The compatibility of cemented carbide valve balls and ceramic valve seats requires comprehensive evaluation based on specific operating conditions. While they offer…

Cemented carbide valve balls themselves have excellent corrosion resistance, especially in resisting atmospheric, acid, alkali, salt corrosion and hydrogen sulfide (H?S) media.…

Cemented carbide valve balls, with their extremely high hardness, wear resistance, and corrosion resistance, are widely used in valves operating under harsh…

Cemented carbide valve balls offer superior performance, but regular maintenance is essential. To ensure stable operation and a long service life, comprehensive…

Cemented carbide valve balls are high-hardness, wear-resistant, and corrosion-resistant precision components, mainly used for valve sealing in the petroleum and chemical industries.…

These safety standards cover multiple dimensions, including material properties, sealing design, process control, and safety certifications, to ensure reliable sealing and safe…