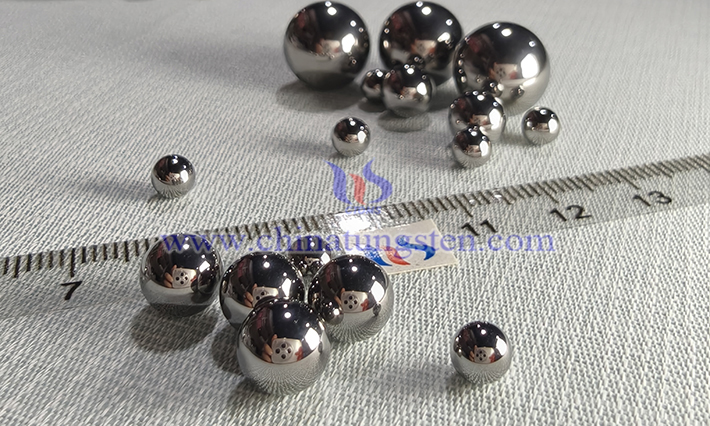

Cemented carbide valve balls are high-hardness, wear-resistant, and corrosion-resistant precision components, mainly used for valve sealing in the petroleum and chemical industries. Based on relevant industry standards (such as GB/T 5243-2006 "Marking, Packaging, Transportation and Storage of Carbide Products") and manufacturers' practical experience, storage specifications primarily focus on moisture prevention, oxidation prevention, impact protection, and maintaining cleanliness to prevent surface oxidation, rust, or mechanical damage.

1. Cemented Carbide Valve Balls Storage Environment Conditions

Dryness and Ventilation: The storage area should be kept dry, clean, and well-ventilated, avoiding humid environments. Relative humidity should be controlled below 80%, and the temperature should ideally be between room temperature (-20℃~60℃) to avoid extreme high or low temperatures that could cause material deformation.

Avoid Oxidation: Cobalt or other binders in carbide are easily oxidized in humid air, leading to surface discoloration or performance degradation. 1. Do not expose to humid, acidic, alkaline, or corrosive gas environments.

2. Cemented Carbide Valve Balls Packaging and Protection

Moisture-proof packaging: Use plastic bags, airtight packaging bags, or dustproof bags for sealed packaging. It is recommended to add a desiccant (such as silica gel) to absorb moisture.

Accident prevention: Individual or small batches of valve balls should be individually wrapped (such as with foam or soft cloth) to avoid mutual friction or impact. Precision valve balls have a high surface finish, and impacts can easily cause scratches or deformation.

Layered storage: For large quantities, use layered racks or boxes to avoid excessive stacking that could deform lower layers.

3. Cemented Carbide Valve Balls Storage Method

Warehouse requirements: Store in a cool, dry indoor warehouse, avoiding direct sunlight and rain. Ventilate on sunny days and seal to prevent moisture on rainy days.

Do not mix: Do not store with acids, alkalis, salts, or other chemicals to avoid chemical reactions.

Regular inspection: For long-term storage, check the integrity of the packaging and the surface condition every 3-6 months. If signs of moisture or oxidation are found, replace the packaging or dry the area immediately.