These safety standards cover multiple dimensions, including material properties, sealing design, process control, and safety certifications, to ensure reliable sealing and safe operation of gas valves under complex conditions such as high pressure, high temperature, and corrosion, effectively preventing gas leaks, fires, and explosions.

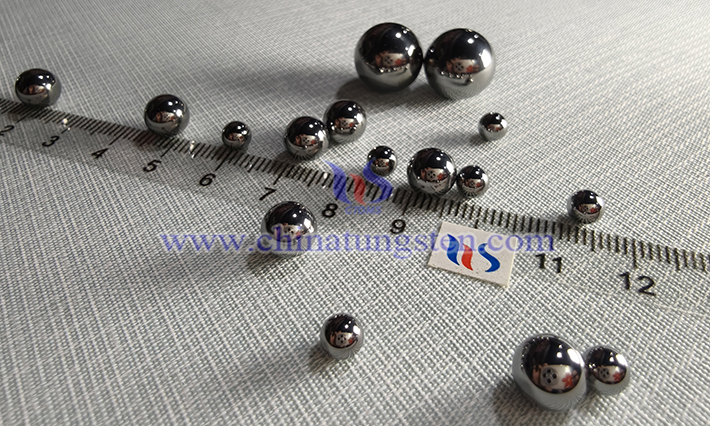

1. Material Properties and Corrosion Resistance: Cemented carbide valve balls are mostly made of tungsten-cobalt-based alloys, possessing high hardness (HRC70 and above), wear resistance, and high-temperature resistance (temperature resistance above 650℃), making them suitable for high-pressure, high-temperature, and corrosive gas environments (such as those containing hydrogen sulfide and chloride ions). 1. Valve body material must be matched to the operating conditions. For example, 316L stainless steel is used for sulfur corrosion resistant environments, duplex steel (2205) for acidic media, and low-temperature steel (LCB) for cold regions. Ensure tensile strength ≥620MPa and yield strength ≥415MPa. The wall thickness should be increased by 20%-30% compared to soft-seal valves to withstand high-pressure impacts.

2. Sealing and fireproof design: A metal-to-metal hard seal structure is adopted, with a sealing surface accuracy of Ra≤0.4μm. Wear is compensated by an elastic pre-tightening mechanism to achieve zero leakage (compliant with API 598/API 6D standards, leakage rate ≤100ppm volume fraction). For fireproofing, a graphite fireproof ring (temperature resistant 450℃-650℃) is installed at the rear of the valve seat, compliant with API 6FA standards, ensuring a seal for 30 minutes in case of fire. The anti-static design uses a conductive spring between the valve body and the ball to achieve grounding, preventing explosions caused by electrostatic sparks.

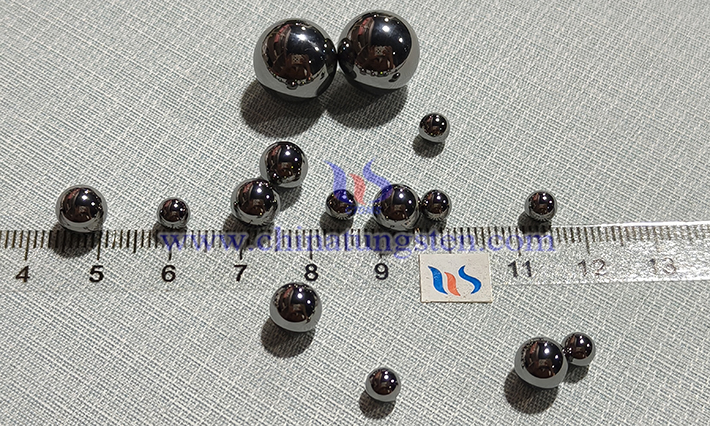

3. Manufacturing Process and Quality Control: Castings must undergo rigorous inspection (e.g., ultrasonic testing, hardness testing). Hard-seal valve ball machining includes turning, drilling, milling, deburring, and rust prevention treatment. Soft seals require an additional wear-resistant layer (e.g., tungsten carbide) and grinding. Key processes such as weld overlay require ultrasonic testing, and the sealing surface hardness must reach HRC65 or higher, and it must pass durability testing (meeting sealing requirements after ≥5000 opening and closing cycles). Raw material consistency must meet certification requirements, such as the key component list management in CQC certification.

4. Safety Certification and Standards: Must comply with national standards such as GB/T 39485-2020 and CJ/T 180-2024, covering airtightness testing (leakage rate ≤50ppm at 1.1 times nominal pressure), shell pressure resistance testing (no leakage at 2.5 times nominal pressure for 3 minutes), and environmental adaptability (temperature -40℃~120℃, salt spray test ≥96 hours without rust). The certification process includes type testing, factory inspection, and post-certification surveillance to ensure product consistency and safety performance.

5. Application and Maintenance Specifications: Select the valve body material according to the pressure rating (e.g., PN1.6MPa for domestic use, PN4.0MPa for industrial use) and media characteristics. During installation, an airtightness test and pressure test are required. Regularly lubricate the valve stem, check for seal wear, and install a gas detection alarm device and an emergency shutdown interlock system. It is recommended to check the sealing performance every 2 years. Valves that have not been used for a long time should be opened and closed periodically to prevent jamming.