Through its superior material properties, cemented carbide valve balls have become a core component in modern industrial wear-resistant control valves, significantly improving…

Through its superior material properties, cemented carbide valve balls have become a core component in modern industrial wear-resistant control valves, significantly improving…

The main applications of cemented carbide valve balls in deep-sea drilling valves are in oil pumps and related valve systems in the…

The application of cemented carbide valve balls in oil pump check valves mainly relies on the precise matching of their material properties…

In high-pressure wellhead operations, cemented carbide ball valves, with their superior tolerance to extreme working conditions, become a core component ensuring the…

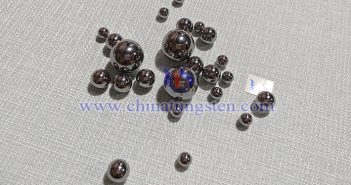

Cemented carbide valve balls are spherical valve cores made primarily of high-hardness, wear-resistant materials such as tungsten carbide compounds. They are commonly…

Cemented carbide valve balls, due to their high hardness, wear resistance, corrosion resistance, and impact resistance, have a wide range of applications…

Cemented carbide, typically a composite material made using powder metallurgy with tungsten carbide as the matrix and metals such as cobalt as…

Cemented carbide valve balls, primarily made of tungsten carbide (WC) as the matrix with the addition of binders such as cobalt or…

Cemented carbide balls are widely used in cryogenic valves (such as ball valves) due to their extremely high hardness, wear resistance, and…

Material selection for cemented carbide valve balls in high-temperature valves requires comprehensive consideration of core indicators such as high-temperature performance, wear resistance,…