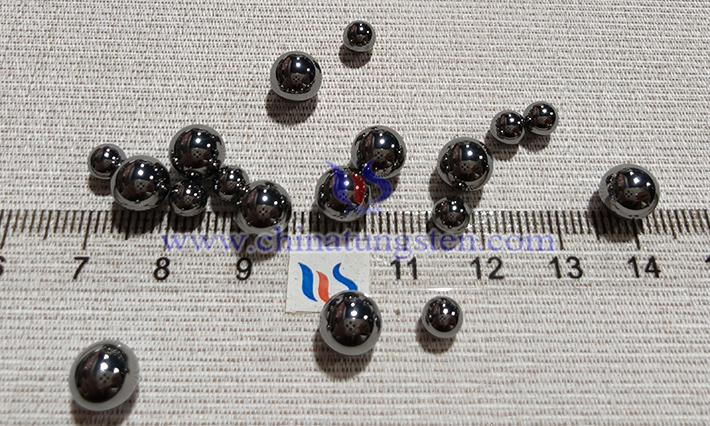

Cemented carbide balls are widely used in cryogenic valves (such as ball valves) due to their extremely high hardness, wear resistance, and corrosion resistance, effectively resisting media erosion and sealing surface wear. However, when used in cryogenic environments, specific precautions must be strictly followed to ensure the safety, sealing performance, and service life of the valve.

1. Material Treatment

Cemented carbide balls and related components (such as valve seat sealing surfaces) require cryogenic treatment, typically immersion in liquid nitrogen, to eliminate residual stress and improve cryogenic impact toughness, preventing material embrittlement and cracking at low temperatures. Valve bodies and covers are mostly made of austenitic stainless steel (such as 304L or 316L) to ensure the face-centered cubic lattice structure maintains toughness at low temperatures. The thickness of the carbide weld overlay should be uniform, and the surface should be ground smooth to achieve a metal-to-metal hard seal, preventing gap leakage during low-temperature contraction.

2. Structural Design

Cryogenic valves typically employ a long-neck bonnet structure, elongating the valve stem to create sufficient space for the vapor column, protecting the stuffing box from direct exposure to the cryogenic medium and preventing packing freezing or leakage. Cemented carbide balls often feature an upstream pressure relief port or a spring-loaded floating seat to achieve automatic pressure relief within the cavity, preventing overpressure and rupture of the valve body due to the vaporization and expansion of residual liquid medium when closed. This is especially important with easily vaporized media (such as liquefied natural gas), otherwise, it could lead to serious safety accidents.

3. Installation and Operation Precautions

When installing the valve, the valve stem should be vertically upward or tilted at a certain angle. Horizontal installation is strictly prohibited to prevent cryogenic medium from filling the bonnet, causing seal failure, or cold energy transfer to the operating handle, resulting in injury. The pressure relief direction is generally upstream and should be clearly marked on the piping diagram. Before installation, the valve cavity must be thoroughly dried to remove any residual moisture, preventing freezing and expansion at low temperatures that could damage components. When welding connections, the valve body should be cooled with water to prevent deformation of the heat-affected zone. During operation, avoid rapid opening and closing to prevent impact. Regularly check the sealing surface for wear, especially in media containing particles.

4. Cleaning and Maintenance

Regular lubricating oil should not be applied to cryogenic valves, as it may solidify at low temperatures, increasing friction. The cemented carbide balls surface has strong self-lubricating properties, but media residue needs to be cleaned regularly. In ultra-low temperature applications, a cold insulation layer is also required, but care should be taken not to cover the pressure relief markings.