The application of cemented carbide valve balls in oil pump check valves mainly relies on the precise matching of their material properties with the functional requirements of check valves. Through high hardness, wear and corrosion resistance, impact resistance, and high-precision sealing, it solves the problems of sealing failure and lifespan under harsh conditions such as high pressure, corrosion, and high-frequency opening and closing in oil extraction.

I. Matching of Cemented Carbide Valve Ball Material Properties with Check Valve Requirements

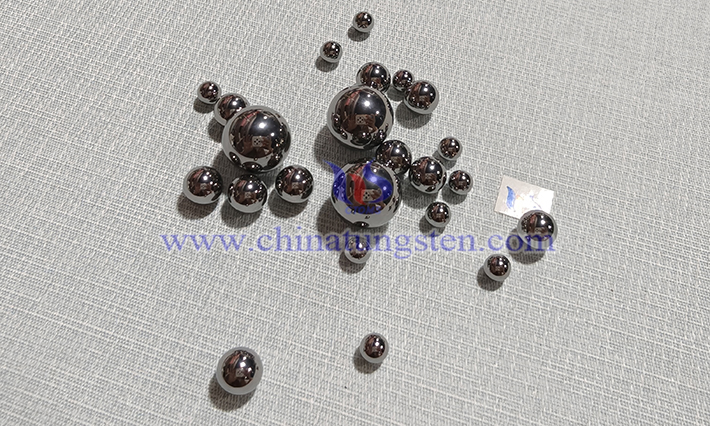

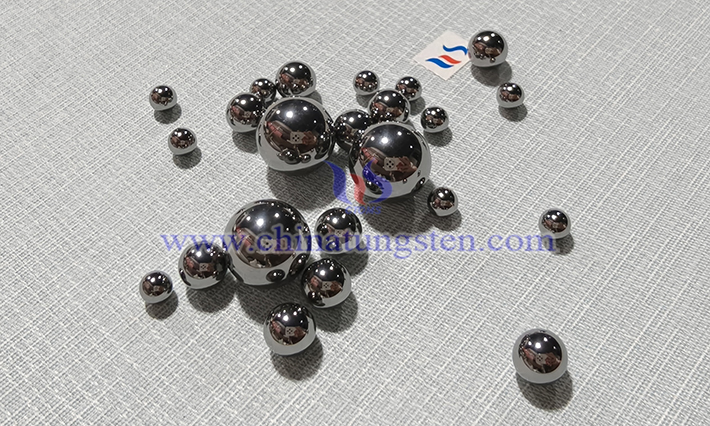

High Hardness and Wear Resistance: Cemented carbide valve balls have a hardness of HRA85 or higher. After hot isostatic pressing, their relative density is close to the theoretical value, and the surface can be polished to a mirror finish. This characteristic results in extremely low frictional loss with the valve seat during frequent opening and closing, effectively resisting wear from sand, salt, and other particulate matter, extending the life of the sealing surface.

Corrosion Resistance and Chemical Stability: In oil extraction, crude oil contains water, gas, wax, gum, asphalt, and corrosive media. Ordinary materials are easily corroded, leading to seal failure. Cemented carbide valve balls, with their stable chemical properties, can withstand long-term contact with corrosive media without chemical reaction, ensuring stable sealing performance.

Impact Resistance and High-Pressure Bearing Capacity: Check valves must withstand multi-directional pressures, including bottom hole flow pressure, liquid column gravity, and rod/tube gravity. The high compressive strength (withstanding 280MPa high pressure) and impact toughness of cemented carbide valve balls ensure structural integrity under high-pressure conditions, preventing deformation or breakage due to pressure shocks.

II. Performance Stability of Cemented Carbide Valve Balls under Extreme Conditions

Sealing Reliability under High-Frequency Opening and Closing: In oil pump operation, the valve ball and seat need to open/close frequently to control oil flow. The mirror-finish surface of the cemented carbide valve ball precisely matches the valve seat, forming a micron-level sealing surface, achieving complete sealing even under high pressure, preventing material leakage and backflow.

Antimagnetic properties prevent magnetic adsorption and leakage: Ordinary pumps and valves are easily magnetized by the Earth's magnetic field downhole, causing metal debris to adhere to the sealing surface and leading to leakage. While cemented carbide valve balls are not antimagnetic, their high-hardness surface reduces debris embedding, and precision machining reduces the roughness of the sealing surface, indirectly reducing the risk of magnetic adsorption and improving sealing reliability.

Performance stability under extreme conditions: In extreme environments such as deep-sea drilling and high-temperature, high-pressure wells, the high strength and corrosion resistance of cemented carbide valve balls are fully demonstrated. Their material stability ensures that the check valve can still function normally in extreme pressures, temperatures, and corrosive media, avoiding downtime for maintenance due to material failure and reducing extraction costs.

III. Improvement of Oil Pump Efficiency and Lifespan by Cemented Carbide Valve Balls

Reduced unplanned downtime: The high wear and corrosion resistance of cemented carbide valve balls significantly extends the service life of check valves, reducing frequent pump inspections due to seal failure and improving the continuity and efficiency of oil well production.

Reduced maintenance costs: Long-term stable operation reduces the frequency of valve ball and seat replacements, lowering spare parts consumption and labor maintenance costs, while improving the overall reliability of the pumping unit.

Adaptability to complex operating conditions: In complex conditions such as sandy wells, heavy oil wells, and high-pressure anti-drainage wells, the high-performance advantages of cemented carbide valve balls are even more prominent, ensuring efficient operation of the pumping unit in harsh environments.