Polishing tungsten beads requires a combination of mechanical and chemical methods, using multi-stage precision operations to achieve a mirror finish. Process parameters…

Polishing tungsten beads requires a combination of mechanical and chemical methods, using multi-stage precision operations to achieve a mirror finish. Process parameters…

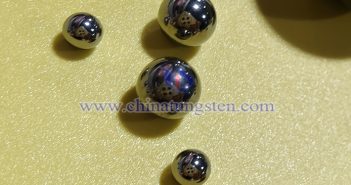

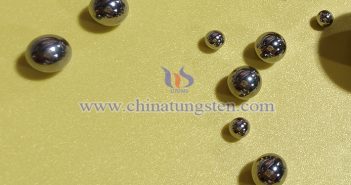

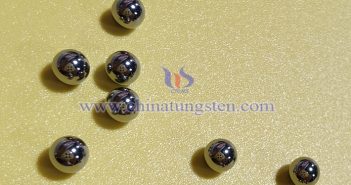

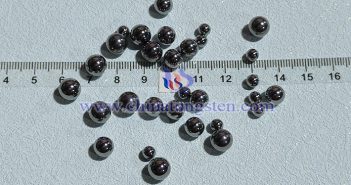

Tungsten beads typically refer to pure tungsten balls, high-density tungsten alloy balls, or cemented carbide balls. Different types have different applications and…

Tungsten beads and zirconia beads are two mainstream high-performance grinding media in the field of ultrafine grinding, commonly used in sand mills,…

Tungsten balls, primarily tungsten steel balls or cemented carbide balls, are made primarily of tungsten carbide (WC) with 6-10% cobalt or nickel…

Tungsten and lead beads are the primary materials for fishing sinkers (weight beads) and are gaining significant attention in modern fishing. Tungsten…

The density of tungsten beads (usually referring to high-density tungsten alloy beads), i.e., the degree to which their relative density approaches the…

As high-density tungsten alloy products, tungsten beads have attracted significant attention in military and engineering fields due to their outstanding kinetic energy…

As a high-density, high-hardness metal product, tungsten beads are widely used in fishing, industrial grinding, and shooting, and their environmental friendliness has…

The thermal conductivity of tungsten beads essentially depends on the thermophysical properties of metallic tungsten. Pure tungsten (W) typically has a thermal…

Tungsten beads typically refer to small spherical particles made of pure or high-purity tungsten. Their conductivity primarily depends on the inherent electrical…