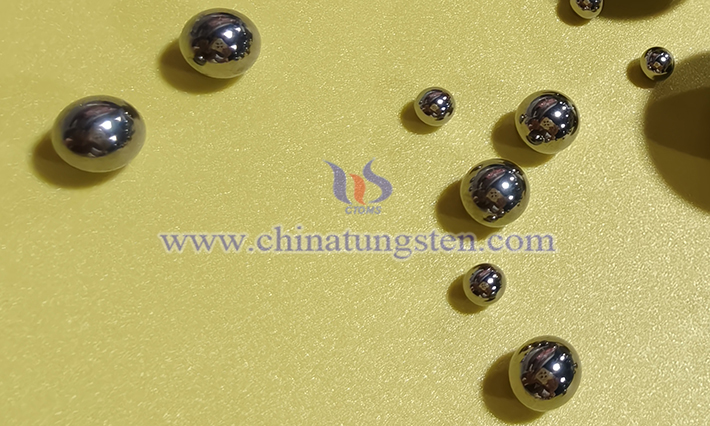

Tungsten balls, primarily tungsten steel balls or cemented carbide balls, are made primarily of tungsten carbide (WC) with 6-10% cobalt or nickel binder, and are produced through high-temperature sintering using powder metallurgy. Steel balls, primarily bearing steel balls or stainless steel balls, are mostly made of high-carbon chromium alloy steel, forged, heat-treated, and precision-ground. These are the two most common precision spherical materials in the industrial field. While similar in appearance, they differ significantly in material, manufacturing process, and performance, and are commonly used in bearings, valves, flow meters, grinding media, pen beads, and other applications.

Performance Comparison of Tungsten Balls and Steel Balls

1. Tungsten balls offer better environmental adaptability.

Tungsten balls have a density of approximately 14.5-15.0 g/cm3, almost twice that of steel balls (7.8-7.9 g/cm3), resulting in greater weight for the same volume and providing higher inertia and stability. In terms of hardness, tungsten balls typically reach 88-92 HRA (equivalent to 1500-1800 HV), far exceeding the 58-66 HRC (approximately 600-800 HV) of steel balls, approaching diamond levels. This gives tungsten balls an overwhelming advantage in resistance to wear, scratches, and deformation: in abrasive media or high-impact conditions, the lifespan of tungsten balls can be 30-100 times longer than that of steel balls. For example, in ball mill grinding media or oil valve ball valves, steel balls are prone to rapid wear leading to leakage, while tungsten balls can significantly extend maintenance intervals.

2. Tungsten balls possess superior corrosion resistance.

Tungsten balls exhibit excellent resistance to chemical media such as acids, alkalis, and salt spray, especially excelling in flow meters or chemical valves containing corrosive fluids; ordinary bearing steel is prone to rust, and while stainless steel balls offer improvements, they are still inferior to tungsten balls. Regarding temperature resistance, tungsten balls can maintain high hardness for extended periods at 400-500℃, while steel balls soften significantly above 200-300℃, making them suitable for high-temperature applications.

3. Tungsten balls have poor toughness.

Tungsten balls are brittle and have weaker impact resistance than steel balls. Under high impact, vibration, or heavy-load impact conditions, steel balls are less likely to chip or shatter.

4. Tungsten balls are more expensive.

Tungsten balls are typically 20-50 times more expensive than steel balls, but in terms of work efficiency, environmental adaptability, and service life, they offer better value for money, especially in applications requiring high wear resistance, corrosion resistance, and high-temperature resistance.

5. Differences in applications between tungsten and steel balls.

Steel balls are primarily used in general bearings, automotive parts, bicycles, power tools, and other mass-market applications; tungsten balls are more commonly found in high-end precision bearings, flow meter valve balls, high-pressure oilfield valves, spraying equipment, hardness tester indenters, military armor-piercing projectile cores, and high-end ballpoint pen beads.