The fundamental reason why tungsten-copper alloy can simultaneously achieve high hardness and conductivity lies in its two-phase composite structure: tungsten provides strength…

The fundamental reason why tungsten-copper alloy can simultaneously achieve high hardness and conductivity lies in its two-phase composite structure: tungsten provides strength…

In the context of engineering, the terms “binder” and “binder phase” in tungsten alloys are often used interchangeably. However, from the perspectives…

The adaptation requirements for tungsten alloy shielding containers in nuclear industry scenarios stem from the particular nature of their service objects: high-activity…

The adaptation requirements for tungsten alloy shielding containers in nuclear industry scenarios stem from the particular nature of their service objects: high-activity…

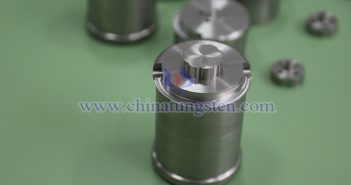

The sealing performance requirements of tungsten alloy shielding containers constitutes the core capability for achieving physical containment of radioactive material and zero…

The corrosion resistance requirements of tungsten alloy shielding containers serves as an important performance guaranteeing surface integrity and geometrical permanence under long-term…

The shielding efficiency requirements of tungsten alloy shielding containers serves as the comprehensive criterion for evaluating radiation protection capability, typically assessed through…

The ductility requirements of tungsten alloy shielding containers serves as the fundamental mechanical assurance that they do not undergo brittle fracture under…

The high-temperature performance requirements of tungsten alloy shielding containers provides the foundation for maintaining dimensional stability, structural integrity, and shielding effectiveness under…

Tungsten alloy shielding containers have developed a relatively mature classification system according to structural form, application scenario, and containment method. The main…