In the context of engineering, the terms "binder" and "binder phase" in tungsten alloys are often used interchangeably. However, from the perspectives of materials science and industrial manufacturing, they actually refer to concepts at different levels and stages. To truly understand the compositional design and performance origins of tungsten alloys, it is essential to clearly distinguish between these two concepts and examine them within the entire powder metallurgy process.

I. What is the binder in tungsten alloys

The binder typically refers to the auxiliary material used during the forming stage. Its core function is not to contribute to the final service performance but to assist tungsten powder or tungsten-based composite powder in achieving sufficient strength and integrity during forming processes such as pressing, injection molding, extrusion, etc.

In the preparation of tungsten alloys, binders primarily appear in the front-end processes of powder metallurgy, such as cold pressing, metal injection molding (MIM), extrusion molding, or additive manufacturing feedstock systems. They coat the powder, fill the gaps between particles, and enable the powder to form stably under external force without cracking or powder loss.

Common forming binders for tungsten alloys include polymeric organic systems, such as paraffin wax, polyethylene, polypropylene, polyoxymethylene, stearic acid, etc., or may be multi-component composite systems. Such binders are completely or almost completely removed during subsequent debinding and sintering processes and do not constitute the final microstructure of the alloy. Therefore, in essence, the binder is a "process material" that addresses whether forming is possible and how stable the forming is, rather than the question of the final performance of the material.

II. What is the binder phase in tungsten alloys

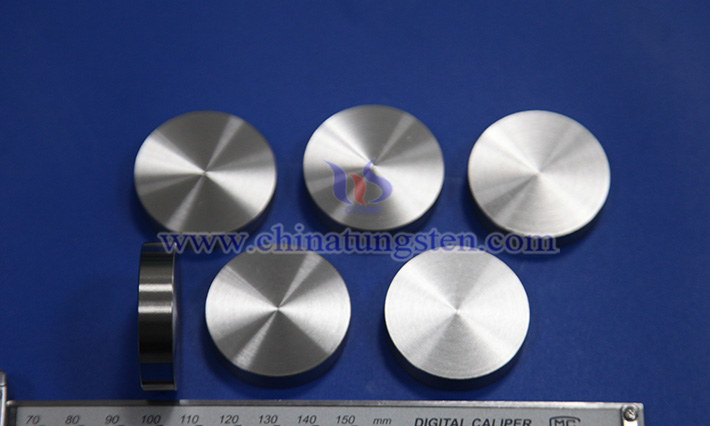

The binder phase is entirely different. It is one of the constituent phases in the final microstructure of a tungsten alloy, existing after high-temperature sintering and participating in load-bearing and service over the long term as a metallic or alloy phase. In most tungsten alloys, tungsten itself acts as the high-melting-point, high-hardness skeleton phase, while the binder phase is responsible for connecting tungsten particles, filling grain boundary spaces, and providing plastic deformation capability under external loads. It is the presence of the binder phase that enables the inherently brittle tungsten material to achieve machinability, toughness, and engineering usability. From a materials mechanism perspective, the binder phase fulfills at least three key functions: (1) achieving densification through liquid phase sintering or diffusion sintering; (2) transmitting loads between tungsten particles through interfacial bonding; and (3) blunting cracks through its own plastic deformation, significantly improving fracture toughness. Therefore, the binder phase is a "performance material" that directly determines the strength, toughness, elongation, magnetic properties, corrosion resistance, and even service reliability of tungsten alloys.

III. Common types of binder phases in tungsten alloys

From the perspective of industrial maturity and application scale, the binder phases in tungsten alloys can be divided into several major categories.

In tungsten-based heavy alloys, the most typical binder phase is the nickel-based system. Nickel-iron and nickel-copper are the two most widely used forms. The nickel-iron binder phase exhibits good wettability to tungsten during sintering, forming a continuous metallic matrix, and achieves a favorable balance between strength and plasticity, making it widely used in structural components, counterweights, and protective parts. The nickel-copper system emphasizes non-magnetic properties and corrosion resistance, making it suitable for precision instruments and special environments.

In cemented carbide systems, tungsten exists in the form of tungsten carbide, and its binder phase is primarily cobalt. Cobalt exhibits excellent wettability to tungsten carbide, forming a stable, continuous grain boundary network, which is key to achieving high hardness alongside certain toughness. With the expansion of application environments, nickel-based or nickel-chromium-based binder phases are also used in corrosion-resistant or non-magnetic cemented carbides.

In functional tungsten-copper materials, copper itself serves as the binder phase. Here, the binder phase not only connects the tungsten skeleton but also undertakes the core functions of electrical and thermal conductivity. Its design objective is not ultimate strength but thermal management and electrical performance.

In recent years, as material design advances toward extreme performance, some new types of binder phases have gradually entered research and small-scale applications, such as intermetallic compound binder phases (e.g., nickel-aluminum systems), medium- or high-entropy alloy binder phases, and multiphase composite binder phases strengthened through nanostructural design. The common feature of these systems is maintaining stable performance under higher temperatures, stronger radiation, or harsher environments.

IV. Core differences between binder and binder phase

If summarized in terms of manufacturing flow and material attributes, the difference between the two can be understood as follows: the binder exists "before forming," serving the manufacturing process; the binder phase exists "after sintering," serving the material performance. The binder is typically an organic or low-melting-point system, removed before sintering; the binder phase is a metal or alloy, permanently retained within the material. The former determines whether manufacturing can proceed smoothly, while the latter determines whether the material is usable, durable, and reliable.

In tungsten alloy design, what truly requires meticulous design and repeated optimization is the binder phase, not the binder. The binder is more of a process engineering issue, whereas the binder phase is a materials science issue. It is precisely through continuous optimization of the binder phase's composition, content, interfacial structure, and phase stability that modern tungsten alloys can achieve a balance among high density, high strength, high toughness, and complex service environments. Understanding this distinction clearly helps avoid conceptual confusion during technical exchanges, procurement communication, and application selection, and enables a more accurate grasp of the true reasons behind performance differences in tungsten alloys.