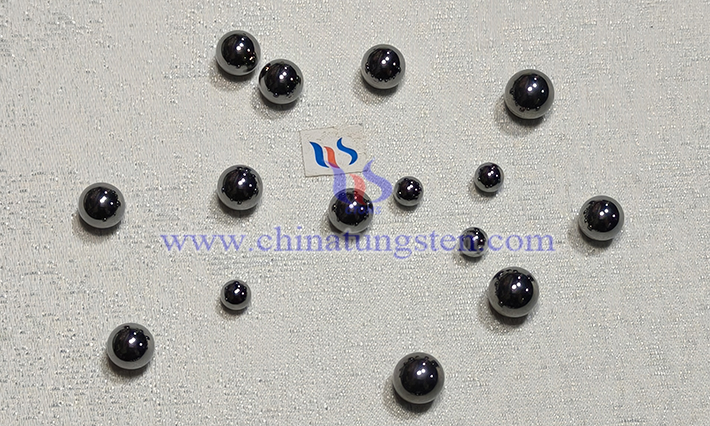

The hardness of tungsten beads is a technical indicator highly related to their specific composition and manufacturing process. High-hardness tungsten beads mainly refer to tungsten carbide beads (cement carbide beads) or high-density tungsten alloy beads.

I. Cement Carbide Beads

Cemented carbide beads use tungsten carbide as a hard framework and cobalt or nickel as a binder metal, sintered using powder metallurgy. Their Vickers hardness is typically higher than 1500 kN/mm2, their Mohs hardness is approximately 9.5, and their Rockwell hardness (HRA) is generally no less than 90.5. This extremely high hardness allows them to scratch glass and even grind harder ceramic materials.

The hardness of cemented carbide beads is mainly controlled by three factors. First is the size and distribution of the tungsten carbide grains; finer, more uniform grains result in higher hardness. Secondly, the content of the binder phase (usually cobalt) is crucial. Reducing the cobalt content can increase hardness, but it also increases brittleness. Finally, the sophistication of the sintering process directly determines the degree of material densification, thus affecting the final hardness. In the practical application of tungsten carbide beads, a trade-off must be struck between hardness, toughness (impact resistance), and wear resistance based on the actual working conditions. Simply pursuing the highest hardness may lead to breakage under impact loads.

Due to its unparalleled hardness, tungsten carbide cemented carbide beads are mainly used as superhard abrasive media for the fine grinding of materials such as alumina, silicon carbide, and boron nitride. They are also used as critical spheres in precision bearings or mechanical valves where extreme wear resistance and precision are required.

II. High-Density Tungsten Alloy Beads

High-density tungsten alloy beads have relatively low hardness. Their main component is tungsten, with the addition of metals such as nickel, iron, and copper to improve sinterability and toughness. Their hardness is commonly measured using Rockwell hardness (HRC), typically ranging from 24 to 36. The core characteristic of high-density tungsten alloy beads is their extremely high density (typically 14.0 to 14.9 grams per cubic centimeter), rather than their ultimate hardness.

The hardness of high-density tungsten alloy beads primarily depends on the alloy element ratios, the phase composition after sintering, and whether subsequent strengthening treatments such as rotary forging are performed.

High-density tungsten alloy beads are widely used in applications requiring weighting, balancing, or radiation shielding, such as in aerospace, medical devices (e.g., collimators), and high-end sporting goods (e.g., golf club weights), leveraging their high density.