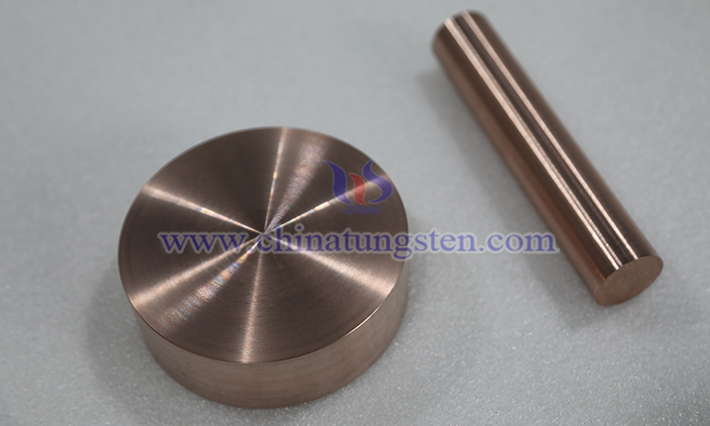

Tungsten-copper alloy is a two-phase composite pseudo-alloy (Pseudo-alloy) produced through powder metallurgy technology. It does not form a solid solution but is a composite material with tungsten and copper phases physically bonded. Its design concept cleverly integrates tungsten skeleton's high melting point, high strength, low thermal expansion coefficient, and arc erosion resistance with copper phase's high electrical conductivity, high thermal conductivity, and excellent plasticity, thereby obtaining a unique combination of properties in engineering materials: "low thermal expansion + high thermal conductivity + arc resistance + high density". Because of this, it has become an irreplaceable key material in high-end technical fields such as power electronics, aerospace, and national defense military industry. The following details the uses by industry, with common mass fractions (W:Cu) ratios, and specific selection should be based on actual working conditions (such as current level, thermal cycle frequency, mechanical load, etc.) and supplier data manuals.

1. Power and Switching Equipment — Arc Contacts / Circuit Breaker Contacts / Vacuum Circuit Breaker Electrodes

Engineering motivation During the instant of circuit breaker opening or closing, a high-temperature arc of thousands of degrees is generated between contacts. The material must withstand this extreme thermal shock, resist melting, spattering, and evaporation, while quickly dissipating heat to extinguish the arc and prevent self-overheating failure.

Common ratios W ≥70 wt% (such as W70Cu30, W80Cu20). Higher tungsten content means stronger skeleton, providing better arc ablation resistance, anti-welding performance, and higher recrystallization temperature.

Typical working conditions Instantaneous arc temperature 3000-20000 K, current up to tens to hundreds of kA, operation lifespan requiring tens of thousands of times or more.

Performance requirements Extremely low arc ablation rate, high thermal conductivity for rapid heat dissipation, high density to suppress arc plasma jet, stable contact resistance, good thermal shock resistance.

Representative applications Medium-high voltage SF6 circuit breakers, vacuum circuit breaker (VCB) contacts, load switches, arrester electrodes.

2. Electrical Discharge Machining (EDM) Electrodes and Precision Mold Electrodes

Engineering motivation EDM processes workpieces using discharge erosion, and the electrode itself also wears. The material needs to withstand high-frequency pulse discharge while maintaining extremely low self-loss and stable geometry to ensure machining accuracy.

Common ratios W70–W90 series (such as W70Cu30, W80Cu20, W90Cu10). Ratio selection is a trade-off between thermal conductivity (copper dominant) and arc erosion resistance (tungsten dominant). W70Cu30 has good machinability and low loss; W80Cu20 is general-purpose; W90Cu10 is used for high-precision, low-loss precision machining.

Typical working conditions High-frequency pulse discharge, machining hard alloys, quenched steel, and other difficult-to-cut materials.

Performance requirements Low electrode loss rate (mg/C), high thermal conductivity to reduce heat-affected zone at discharge points, sufficient strength and hardness to prevent deformation, good machinability (can be ground, wire-cut).

Advantage explanation Compared to pure copper or graphite electrodes, tungsten-copper electrodes have lower loss, faster machining speed, higher surface finish, and better edge retention when machining hard alloys and complex precision molds.

3.Resistance Welding Electrodes

Engineering motivation During welding, electrodes need to withstand huge pressure and current, while also adhering to the welded metal (such as galvanized steel sheet, aluminum alloy). The material needs high electrical conductivity to reduce self-heating, while having high hardness and high recrystallization temperature to resist deformation and wear.

Common ratios W70–W80 (such as W75Cu25). Balances electrical conductivity and wear resistance, sometimes adding small amounts of other elements (such as Ni, Co) to improve sintering performance.

Typical working conditions High pressure (hundreds to thousands of Newtons), high current (several kA to tens of kA), cyclic operation.

Performance requirements High hardness (HRB > 100), high electrical conductivity (≥45% IACS), excellent anti-softening ability and anti-adhesion performance.

4. Electronic Packaging and Thermal Management Materials — Chip Carriers / Power Device Substrates

Engineering motivation Modern power semiconductors (such as IGBT, SiC, GaN) have extremely high chip power density, and their packaging substrates must solve two core problems: ① efficiently conduct heat away; ② thermal expansion coefficient (CTE) must match chip materials (such as Si, SiC, GaAs), otherwise huge stress will be generated during thermal cycling, leading to chip cracking or solder layer failure.

Common ratios WCu10/90 to WCu30/70 (such as W85Cu15, W80Cu20, W70Cu30). Higher tungsten content gives lower CTE (better matching semiconductor chips), but thermal conductivity (TC) decreases accordingly. W80Cu20 is a commonly used compromise, with CTE (~7.0×10??/K) relatively close to silicon (~4.2×10??/K) while maintaining high thermal conductivity.

Typical working conditions High power density (>100 W/cm2), operating temperature -55°C to 150°C or higher, continuous thermal cycling.

Performance requirements Low thermal expansion coefficient matching chip materials, high thermal conductivity (>150 W/m·K), high stiffness and strength, good vacuum sealability and weldability.

5. High Heat Load Components — X-Ray Tube Target Backing / Laser Heat Dissipation Base

Engineering motivation In rotating anode X-ray tubes, electron beam bombards tungsten target to produce X-rays, with more than 99% energy converted to heat, forming extremely high local heat flux density. Backing material needs extremely high thermal conductivity to quickly transfer heat to the cooling system, while high-density tungsten phase can effectively block scattered rays.

Common ratios W70–W90 (such as W90Cu10, W80Cu20, W70Cu30). High tungsten content provides high density and high-temperature strength, copper phase forms efficient heat conduction channels.

Typical working conditions Instantaneous local heat flux density up to kW/mm2 level, requiring forced water or oil cooling.

Performance requirements Extremely high transient and steady-state heat carrying capacity, excellent thermal fatigue performance, high density (also serving as radiation shielding), reliable connection with target material (usually pure tungsten or tungsten-rhenium) (brazing or diffusion welding).

6. Aerospace and National Defense Military — Gas Rudder / Nozzle Throat Liner / Counterweight Blocks

Engineering motivation Missile gas rudders, solid rocket engine nozzle throat liners, and other components need to withstand ultra-high temperature, high-speed gas flow scouring, and thermal shock in atmospheric and space environments. Tungsten-copper material can rely on copper evaporation heat absorption (sweating cooling) and tungsten skeleton stability in short time to maintain component shape.

Common ratios According to specific parts and temperature, tungsten content is usually very high (W80-W90), sometimes using gradient functional material design.

Typical working conditions Short working time (tens of seconds), but extreme environment (high temperature, high pressure, high enthalpy gas flow).

Performance requirements Extremely high high-temperature strength, excellent thermal shock resistance, particle erosion resistance, certain "sweating cooling" effect.

7. Plasma and Discharge Equipment Components — Plasma Spraying Electrodes / Arc Ejectors

Engineering motivation As cathode or anode of plasma arc, the material works under ten-thousand-degree high-temperature plasma arc, withstanding strong ion bombardment and heat flow impact.

Common ratios High tungsten content (usually W≥75%), to ensure low ablation rate and long lifespan of electrode under arc.

Typical working conditions High-temperature plasma arc (>10000 K), high-frequency arcing.

Performance requirements Extremely high arc ablation resistance, low electron work function, high thermal conductivity to reduce electrode operating temperature, uniform microstructure to ensure stable arc.

8. High-Density Counterweights and Balance Blocks / Local Radiation Shielding

Engineering motivation Utilizing tungsten's high density to achieve maximum mass concentration in limited space, used in aerospace vehicle inertial navigation systems, gyroscopes, aircraft rudder counterweights, mobile phone vibration motors, etc. At the same time, the presence of copper phase makes it easier to process and connect than pure tungsten.

Common ratios W90–W97 (such as W93Cu7, W95Cu5). Pursuing ultimate density, copper mainly as binder.

Typical working conditions Space limited, requiring high volume-to-mass ratio, possibly accompanied by vibration and temperature changes.

Performance requirements High density (>17 g/cm3), good dimensional stability and mechanical strength.