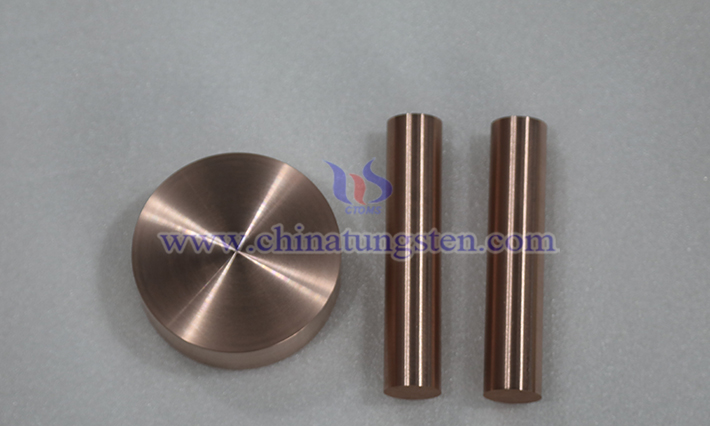

Tungsten-copper alloy contact refers to an electrical contact component (i.e., contact) made of tungsten-copper alloy material used in high-voltage or high-current switching equipment such as electrical switches, circuit breakers, and relays. It is an important functional component in high-temperature and high-current environments, mainly used for conduction and withstanding the electric arc generated during switching operations.

1.Material Composition of Tungsten-Copper Alloy Contacts

Tungsten (W): High melting point (3422°C), high hardness, mainly providing arc ablation resistance and mechanical strength.

Copper (Cu): Good electrical conductivity, high thermal conductivity, mainly providing excellent electrical conductivity and heat dissipation performance.

Alloy ratio: Typically tungsten content is between 50% and 90%, with copper supplementing electrical and thermal conductivity.

2.Functional Characteristics of Tungsten-Copper Alloy Contacts

High-temperature resistance: Tungsten can withstand instantaneous high temperatures from switching arcs, not easily melting or deforming.

Good electrical conductivity: The copper component ensures the contact's electrical conductivity, reducing resistance.

Fast heat dissipation: Copper's good thermal conductivity helps quickly reduce local temperature at the contact.

Arc ablation resistance: Tungsten-copper alloy can withstand multiple breaking arcs, extending contact lifespan.

High mechanical strength: Tungsten provides hardness and wear resistance, making the contact less prone to wear or cracking during switching operations.

3.Typical Applications of Tungsten-Copper Alloy Contacts

High-voltage circuit breaker contacts

Relay and contactor contacts

Arc furnace and vacuum switch contacts

Various switching equipment requiring resistance to high-temperature arcs and high currents.