Compared to traditional metals that struggle to balance high-temperature performance, thermal conductivity, and wear resistance, nano tungsten-copper excels in extreme environments, while the core demands in the aerospace field are precisely lightweight, high specific strength, high-temperature impact resistance, ablation resistance, and strong thermal management capabilities.

The applications of nano tungsten copper in the aerospace field include manufacturing rocket throat liners, heat dissipation bases for high-power electronic modules, etc.

1. Main Application Directions of Nano Tungsten-Copper in the Aerospace Field

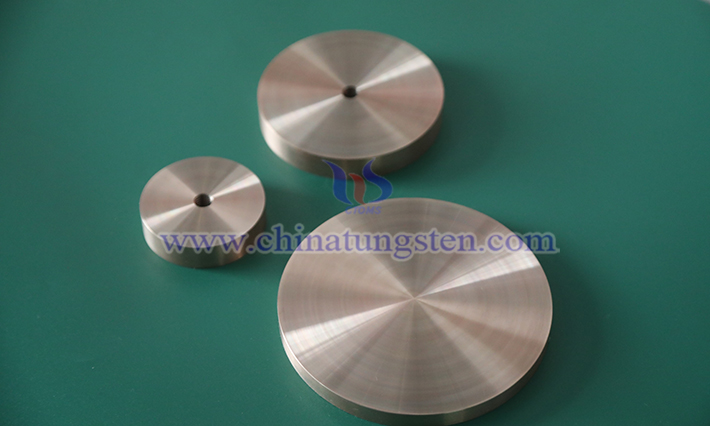

Rocket nozzle nano tungsten-copper throat liner/nozzle sleeve nano tungsten-copper heat dissipation structure Nano tungsten-copper with high thermal conductivity can be used as cooling substrates in local high-temperature zones of rocket engines. It can withstand transient temperatures of thousands of degrees and thermal shocks.

Nano tungsten-copper heat dissipation materials for spacecraft power management and RF components Used as heat dissipation bases for high-power electronic modules (laser communication, radar, high-power amplifiers). The nano structure ensures more uniform thermal expansion, preventing solder joint failure in devices.

Nano tungsten-copper structural components for thermal control of high-power devices in satellites Such as in solar inverters and high-current switches as nano tungsten-copper materials for heat dissipation and electrical contact. In high-speed flight vehicles, the internal nano tungsten-copper thermal diffusion layer of the nose cone/thermal protection components (non-direct ablation layer) plays the role of rapidly diffusing heat under extremely high heat flux, avoiding local hot spots.

2. Role Mechanism of Nano Tungsten-Copper in the Aerospace Field

Nano interfaces make the material less prone to thermal fatigue cracking; high thermal conductivity reduces thermal gradients, protecting sensitive components; high hardness and wear resistance are suitable for long-term cyclic use.

3. Industrial Significance of Nano Tungsten-Copper in the Aerospace Field

In directions such as hypersonic flight and reusable rockets, material lifespan is the bottleneck. Nano tungsten-copper can significantly reduce thermal fatigue damage rates and is considered a leading candidate for the next generation of high-thermal-conductivity and thermal-shock-resistant metals.