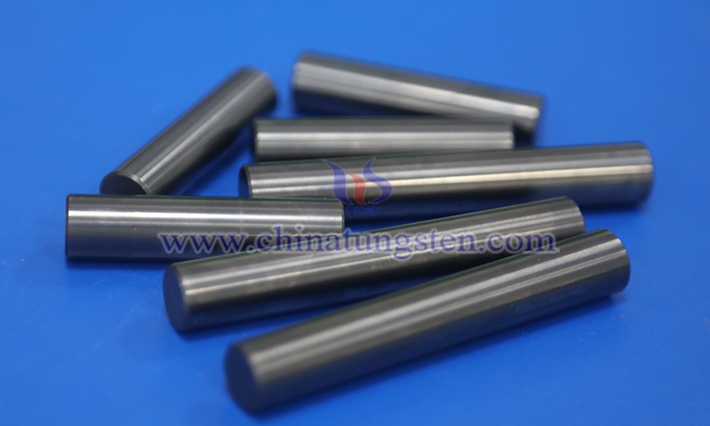

Cemented carbide rods are mainly and most importantly (accounting for more than 70% of the production) used as materials for cutting tools and molds, especially high-performance cutting tools for processing difficult-to-machine materials such as steel, stainless steel, titanium alloys, aluminum alloys, and composite materials. They are irreplaceable basic materials in modern manufacturing.

The main uses of cemented carbide rods are as follows:

1.Manufacturing cutting tools (the largest proportion) Various solid cemented carbide round rods are directly used to make milling cutters, drills, reamers, taps, milling cutter blanks, etc. Cemented carbide rods with coolant holes are specially used to produce high-performance tools such as internal cooling drills and milling cutters.

2.Mold materials Cold heading dies, cold extrusion dies, wire drawing dies, cold upsetting dies, powder metallurgy dies, and other stamping and drawing molds that require high wear resistance and high compressive strength. Cemented carbide rods are often used as mold core rods or top hammer materials.

3.Measuring tools and wear-resistant parts Plug gauges, ring gauges, snap gauges, gauge rods, gauge blocks, and other precision measuring tools. Various wear-resistant shafts, bushings, guide pillars, ejector pins, support rods, mechanical seal rings, and other wear-resistant components.

4.Mining and engineering tools Cemented carbide drill rod materials for geological exploration. Cemented carbide teeth or rod bodies for rock drilling tools, tunneling tools, and impact drilling tools.

5.Structural parts and support parts Wear-resistant support rods, center shafts, and mandrels in high-precision equipment. High-precision cemented carbide rod materials used for processing in the 3C industry (mobile phones, middle frames).

6.Other special purposes Medical surgical tools, dental drill bits. Micro-diameter cemented carbide rods for watch processing. Fishing gear counterweights (tungsten steel sinkers). Pre-sintered rod materials for high-density alloys (such as tungsten-nickel-iron, tungsten-nickel-copper).