A tungsten alloy gyroscope counterweight is a high-density alloy component primarily composed of tungsten as the base (usually dominant content), alloyed with elements such as nickel, iron, and copper. It is specially used in gyroscope systems as a balancing component to adjust the center of gravity distribution and improve the operational stability of the system. This counterweight utilizes the high-density characteristics of tungsten alloy to provide substantial weight within a limited space, thereby avoiding the toxicity issues of lead while addressing the defect of steel being prone to deformation under high-speed rotation conditions. For tungsten alloy gyroscope counterweight products, please contact CTIA GROUP LTD: [email protected], 0592-5129595. For more information on tungsten alloy gyroscope counterweights, please visit: http://www.tungsten-alloy.com/index.htm

I. Working principle of tungsten alloy gyroscope counterweight

The gyroscope relies on a high-speed rotating rotor to maintain directional stability, while the counterweight compensates for manufacturing deviations or dynamic imbalances through weight distribution, ensuring uniform rotor rotation and reducing vibration and precession. Specifically, the counterweight is placed on the rotor or control system, utilizing its high density to generate sufficient moment of inertia and optimize the center of gravity position. In aviation gyroscopes, it can store kinetic energy of the rotating flywheel or adjust the oscillation frequency of the laser beam; in satellite applications, it ensures balance during orbit insertion. Through these mechanisms, the counterweight enhances the sensitivity and control accuracy of the gyroscope, maintaining reliable operation of the system under extreme conditions.

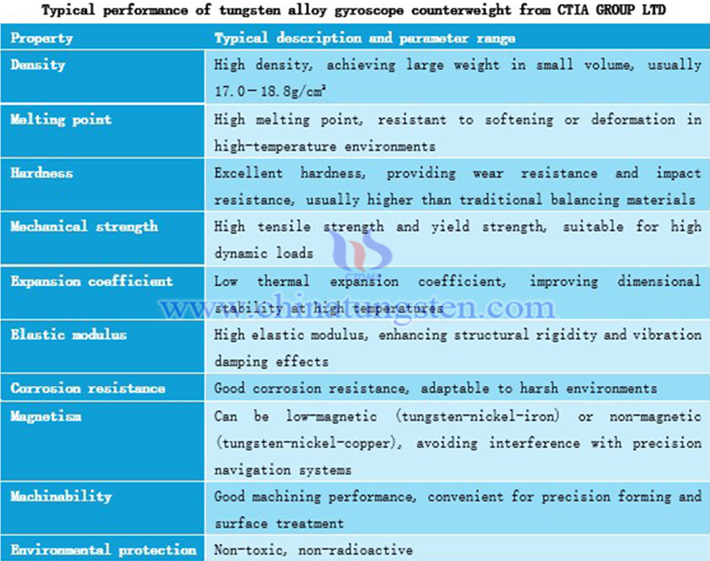

II. Performance of tungsten alloy gyroscope counterweight

The tungsten alloy gyroscope counterweight from CTIA GROUP LTD, with its excellent comprehensive performance, has become an ideal choice for balancing components in precision navigation systems. Its high-density characteristic enables maximum weight concentration within a limited volume, facilitating center of gravity adjustment in gyroscopes; high melting point and low thermal expansion coefficient improve dimensional stability in high-temperature environments, avoiding softening and deformation; high hardness and mechanical strength provide excellent impact resistance and wear resistance, suitable for high dynamic load conditions. At the same time, high elastic modulus enhances structural rigidity, delivering superior vibration damping effects to effectively suppress rotor deviations; magnetism can be adjusted to low-magnetic or non-magnetic to avoid interference with precision systems. In addition, the product features non-toxic environmental protection and excellent machinability. These characteristics work synergistically, enabling tungsten alloy counterweights to perform outstandingly in fields such as aviation gyroscopes, satellite attitude control, missile inertial navigation, and laser/fiber optic gyroscopes, not only improving system accuracy and reliability but also supporting small-volume design and long-life applications.

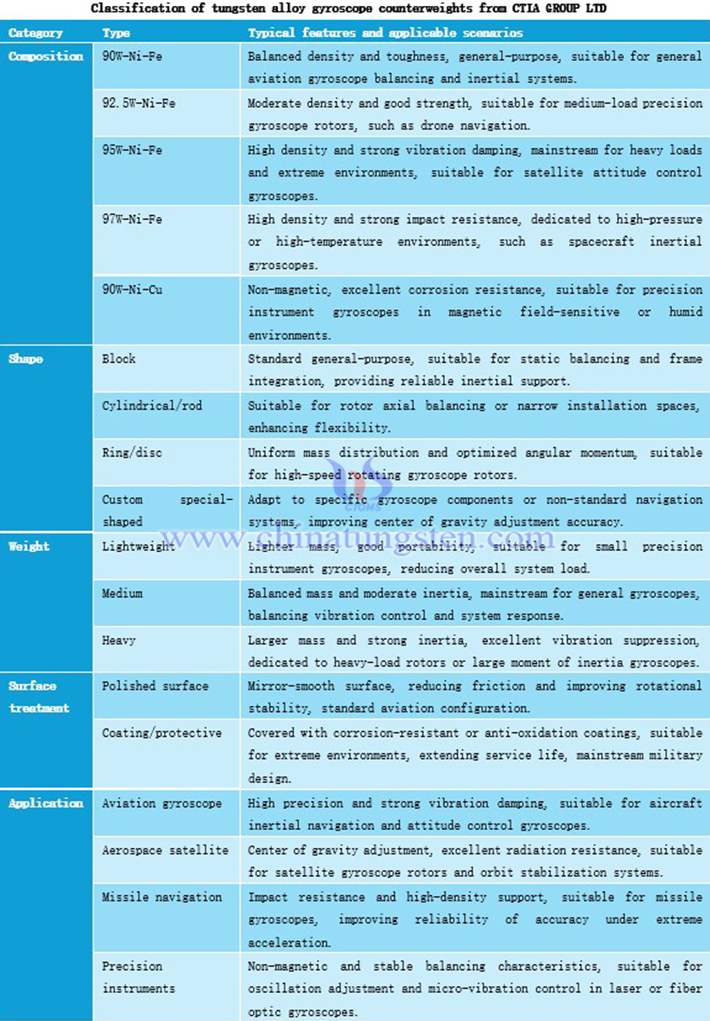

III. Classification of tungsten alloy gyroscope counterweights

The tungsten alloy gyroscope counterweights from CTIA GROUP LTD offer flexible selection in terms of composition, shape, weight, and surface treatment to adapt to the needs of different gyroscope systems. In terms of composition, the tungsten-nickel-iron series balances density and toughness, with high-density models offering excellent impact resistance and vibration damping, suitable for heavy-load scenarios in aerospace; the tungsten-nickel-copper series provides non-magnetic properties and superior corrosion resistance, suitable for environments sensitive to magnetic fields. Shape designs include block, cylindrical/rod, etc., taking into account general installation and adaptation to narrow spaces, while ring/disc structures optimize mass distribution and angular momentum conservation under high-speed rotation. Weights are divided into light, medium, and heavy categories to match system load and vibration control requirements. Surface treatments optionally include polished surfaces to enhance rotational stability or coatings for protection to improve durability in extreme environments, making them important balancing components for high-precision gyroscopes.

IV. Production method of tungsten alloy gyroscope counterweight

The production of tungsten-nickel-iron alloy (W-Ni-Fe) gyroscope counterweights from CTIA GROUP LTD primarily adopts powder metallurgy process, which is the mainstream and mature preparation method in the industry. The production steps of the powder metallurgy process mainly include (1) raw material pretreatment and batch mixing, (2) forming, (3) sintering, and (4) post-processing. For complex shapes or high-precision components, the following auxiliary or alternative processes can be adopted: metal injection molding (MIM) or additive manufacturing (3D printing). Metal injection molding: Mix powder with binder to form feedstock, inject to mold complex special-shaped green bodies, followed by debinding and sintering. The advantage is near-net forming, reducing machining volume, suitable for thin-walled, small precision parts. Additive manufacturing: Use laser or electron beam selective melting of powder to build complex structures layer by layer. Suitable for customized, high-performance components in military and aerospace fields, capable of achieving internal cavities or gradient structures difficult with traditional processes.

During the production process of tungsten alloy gyroscope counterweights, it is necessary to control raw material purity, mixing uniformity, sintering temperature, and atmosphere. These factors affect the core properties such as density, strength, and magnetism of the alloy. The process selection should comprehensively consider product shape, precision requirements, production batch, and cost to achieve the optimal balance between efficiency and quality.

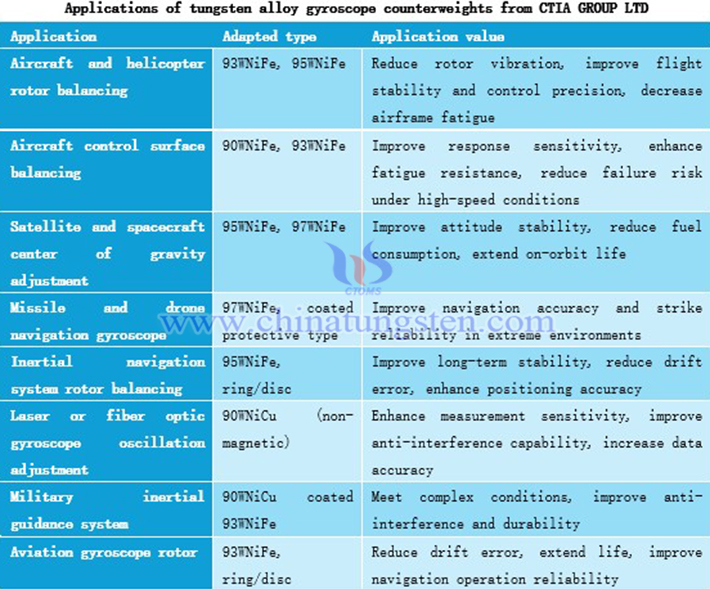

V. Applications of tungsten alloy gyroscope counterweight

The tungsten alloy gyroscope counterweights from CTIA GROUP LTD offer flexible selection to adapt to various gyroscope system requirements. The tungsten-nickel-iron series excels in high density and strong vibration damping, suitable for heavy-load applications such as aviation rotor balancing and satellite attitude control; the tungsten-nickel-copper series highlights non-magnetic and corrosion-resistant characteristics, ideal for magnetic field-sensitive scenarios such as laser/fiber optic gyroscopes.