The production process of cemented carbide rods is a complex and rigorous process, mainly covering key steps such as raw material preparation, powder preparation, forming, sintering, and post-processing. The following is a detailed introduction to these steps:

I. Raw material preparation

Raw material selection: The core raw materials for cemented carbide rods include carbide powders (such as tungsten carbide WC, titanium carbide TiC) and binder powders (such as cobalt Co, nickel Ni). The purity of carbide powders must be ≥99.9%, the particle size is selected according to product requirements, and the particle size distribution must be uniform. Binder powders need to have good plasticity and sintering activity to ensure the formation of a continuous binder phase after sintering.

Raw material pretreatment: Including impurity removal and drying. Impurity removal uses acid washing to remove surface oxides, oil stains, and other impurities from the raw materials to avoid affecting the alloy's densification and corrosion resistance. Drying is carried out through vacuum drying or hot air drying to remove moisture, preventing powder agglomeration during ball milling or pore formation during sintering.

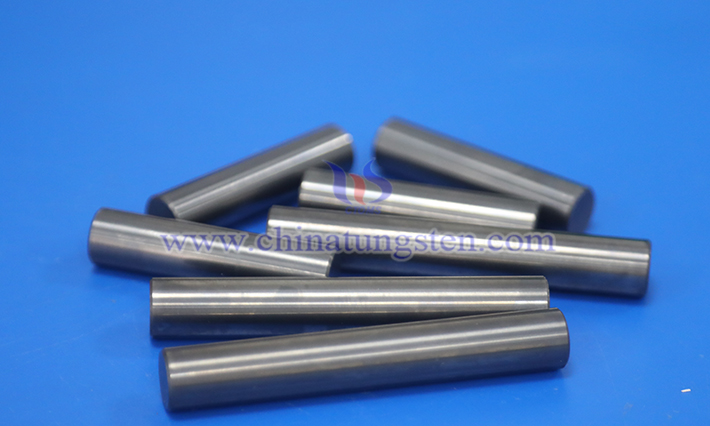

CTIA GROUP LTD Cemented Carbide Rods Pictures

II. Powder preparation

Mixing and ball milling: The carbide powders and binder powders are put into a ball mill according to the formula ratio, and powder uniform mixing and particle refinement are achieved through mechanical grinding. The ball milling medium uses inert media such as anhydrous ethanol or kerosene, and process parameters such as ball-to-material ratio, rotation speed, and time need to match the raw material particle size and mixing target.

Drying and sieving: After ball milling, the medium is removed through vacuum distillation or low-temperature drying to obtain uniformly mixed powder. Subsequently, it is sieved through a vibrating screen to remove unbroken agglomerated particles, ensuring consistent powder particle size.

III. Forming

Die pressing: Suitable for the production of short rod materials. The cemented carbide powder is pressed and formed through a mold, which can be formed in one step, reducing waste products and simplifying wire cutting processes.

Extrusion forming: Suitable for producing longer products with constant cross-section and complex shapes, mainly cemented carbide rods. The extrusion pressure depends on the performance of the plasticized powder, and poor extrusion often causes defects such as cracks and density differences.

Isostatic pressing: Suitable for complex shapes or large-sized products, pressure is transmitted through a liquid medium to achieve three-dimensional uniform pressing of the blank. The blank density uniformity of isostatic pressing is better than die pressing, suitable for preparing thick-walled or special-shaped parts with no internal defects.

Injection molding: For micro and precision parts, the mixed powder and binder are made into feedstock, which is injected into the mold under high temperature and high pressure through an injection molding machine. Subsequent debinding, pre-sintering, and other treatments are required.

CTIA GROUP LTD Cemented Carbide Rods Pictures

IV. Sintering

Pre-sintering treatment: Including dewaxing/debinding and pre-sintering. Dewaxing/debinding removes the binder in the blank to avoid pore formation during sintering. Pre-sintering is carried out at a lower temperature for a short time to remove residual organic matter, initially sinter the particles, and improve the strength of the blank.

Sintering process: Vacuum sintering or hot pressing sintering is adopted, with holding at high temperature for a certain time to achieve solid-phase sintering and liquid-phase sintering of the powder. During the sintering process, the atmosphere, heating curve, and cooling stage need to be controlled to avoid cracking of the blank due to thermal stress and to ensure the precipitation morphology of the Co phase.

V. Post-processing

Finishing processing: Including grinding, polishing, electrical discharge machining, etc., used to improve the precision and surface quality of the sintered body.

Heat treatment and coating: Aging treatment eliminates sintering internal stress, stabilizes the structure, and improves dimensional stability. Surface coating adopts chemical vapor deposition or physical vapor deposition technology to form a hard coating on the surface, reducing the friction coefficient and improving wear resistance.

Quality inspection: Testing physical and chemical properties such as density, hardness, transverse rupture strength, as well as observing the microstructure through metallographic microscope and SEM to ensure that the product quality meets the standards.