The pressing forming of cemented carbide rods usually adopts three methods: cold isostatic pressing, die pressing, and extrusion forming.

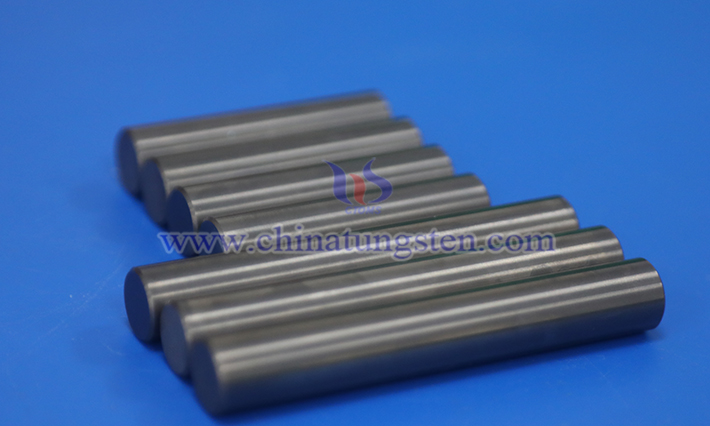

CTIA GROUP LTD Cemented Carbide Rods Pictures

I. Cold Isostatic Pressing (CIP) Forming

Press-cut method: The carbide powder after grinding and sieving is pressed into blocks, then subjected to cold isostatic pressing. This process uses a small amount of plasticizer (such as paraffin or polyethylene glycol), and if the pressure is high enough (400MPa), binder may even be omitted. The formed rod surface is rough and requires subsequent grinding and turning processing.

Wet bag method: The mold is uniformly pressurized in a high-pressure liquid (about 200MPa). The specimen size is limited by the mold cavity, not suitable for mass production, and mainly used for large-diameter rods.

Dry bag method: Different fluids are used as pressure transmission media, the mold is semi-fixed, and blank loading and unloading are operated in a dry state. It has a high degree of automation, short operating cycle, suitable for batch forming, can produce rods up to 400mm in length, and uses a small amount (1%-1.5%) of paraffin or polyvinyl alcohol during forming. This method can also produce rods with cooling channels, but the positional accuracy of the channels is lower.

II. Die Pressing

Horizontal pressing: The upper and lower punches of the mold are designed with circular cross-sectional shapes, and the powder is pressed between the punches. The length of the formed rod is limited by the mold and press size. Due to the uneven pressure on powder particles from the semi-circular punches, voids are easily generated at the blank parting line, which may form cracks after sintering.

Vertical pressing: Similar to the horizontal pressing process, the formed rod is limited by the press stroke and difficult to eject in the vertical direction.

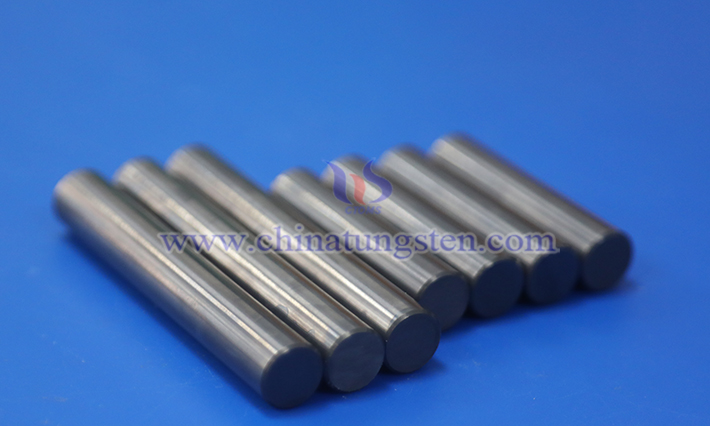

CTIA GROUP LTD Cemented Carbide Rods Pictures

III. Powder Extrusion Molding (PEM)

Process principle: After mixing the powder with binder and plasticizer, it is extruded through an extrusion die hole to form a green compact of the required shape and size. This process combines traditional plastic molding with modern powder metallurgy technology, capable of forming profiled parts with constant cross-section and unlimited length, operated under low temperature and low pressure.

Technical advantages: Product length is not limited, longitudinal density is uniform, forming continuity is strong and efficiency is high, suitable for producing precision components such as circuit board micro drills and automotive joint rods.

Key technologies: Involve original powder selection (such as WC-Co powder preparation technology), binder system updates (development from paraffin to multi-component systems), mixing process optimization (ensuring uniform powder coating), extrusion die design (requiring experience accumulation and CAD system improvements), and other aspects.