Controlling the uniformity of cemented carbide rods involves the entire manufacturing process from raw materials to finished products. It requires high-quality raw materials, highly uniform mixing and granulation, forming techniques that maintain uniformity, precisely controllable sintering and densification processes, as well as strict inspection and feedback control throughout the entire process.

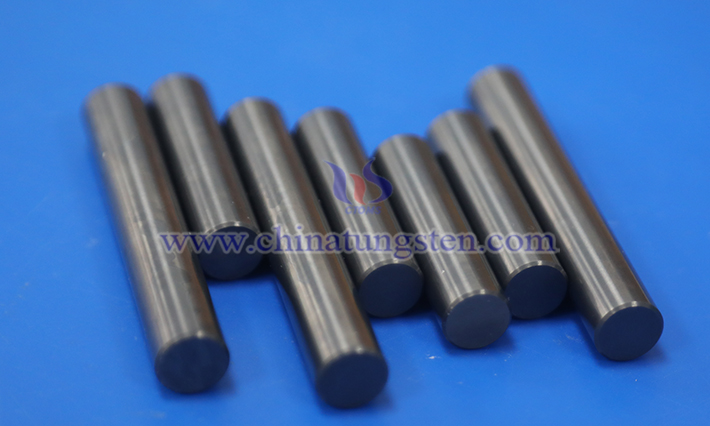

CTIA GROUP LTD Cemented Carbide Rods Pictures

1.Control of raw material powders

Powder quality: Select high-purity, low-impurity tungsten carbide (WC) powder and binder phase powders such as cobalt (Co). The oxygen content and impurity elements (such as Fe, Mo, etc.) in the powders must be strictly controlled.

Powder particle size and distribution: The particle size, particle size distribution, and morphology of the powders must be uniform and stable. Using submicron or ultra-fine powders with narrow particle size distribution is beneficial for improving uniformity, but agglomeration must be prevented. Advanced grinding and classification techniques (such as air classification) are key.

2.Mixing and grinding process

Optimization of ball milling process:

Grinding media and time: Use appropriate grinding media (such as cemented carbide balls), optimize the ball-to-material ratio, grinding time, and rotation speed to ensure thorough and uniform mixing of WC and Co powders, forming a uniform slurry.

Solvents and additives: Select suitable grinding solvents (such as alcohol or acetone) and dispersants to prevent powder agglomeration and ensure the stability and uniformity of the slurry.

Spray drying: The uniform slurry is spray-dried to form mixed granules. It is necessary to precisely control the drying temperature, rate, and atomization parameters to ensure uniform composition of the granules, good flowability, and no segregation.

3.Forming process

Pressing technology:

Isostatic pressing: Compared to unidirectional or bidirectional die pressing, cold isostatic pressing (CIP) can significantly improve the density uniformity and structural uniformity of the green compact, making it the preferred method for producing high-performance cemented carbide rods.

Injection molding (MIM): For complex shapes or small-diameter rods, MIM can provide excellent uniformity, but requires precise control of the binder system and debinding process.

Green compact density control: Ensure the density difference in various parts of the green compact is minimized.

CTIA GROUP LTD Cemented Carbide Rods Pictures

4.Sintering process

Debinding and pre-sintering: Before sintering, the forming agents (such as paraffin) must be completely and uniformly removed to prevent carbon residues or pore formation.

Sintering process selection:

Low-pressure sintering (LPS) or vacuum sintering: These are the most commonly used methods. Precisely control the sintering temperature, heating rate, holding time, and cooling rate, especially the sintering atmosphere, to prevent decarburization or carburization and ensure uniform distribution of the liquid-phase cobalt.

Hot isostatic pressing (HIP): Performing hot isostatic pressing after sintering is the most effective means to eliminate residual pores, improve the densification and uniformity of cemented carbide materials. It can close internal microscopic pores, bringing the material properties to or close to theoretical values.

Sinter-HIP integrated furnace: An advanced integrated process that completes sintering and hot isostatic pressing in the same equipment, offering higher efficiency and better uniformity.

5.Process and quality inspection

Online inspection: Real-time monitoring of powder particle size, granule flowability, green compact density, etc., during mixing, spray drying, pressing, and other stages.

Finished product inspection:

Physical properties: Test density (density gradient) and hardness uniformity at different locations.

Microstructure analysis: Observe the uniformity of WC grain size distribution and cobalt phase distribution through metallographic microscope and scanning electron microscope (SEM), and check for defects such as pores, cobalt pooling, η-phase, etc.

Non-destructive testing: Use ultrasonic flaw detection and other methods to detect internal cracks, large pores, and other macroscopic defects.

6.Equipment and automation

Equipment stability: Ensure stable operation of key equipment such as ball mills, spray drying towers, isostatic presses, and sintering furnaces, with uniform temperature and pressure fields.

Automation and intelligence: Adopt automated production lines and process control systems (such as MES) to reduce human intervention and ensure precise and repeatable process parameters.