Whether the surface of cemented carbide rods requires grinding processing should be comprehensively judged based on their application scenarios, precision requirements, surface quality demands, and subsequent processing procedures.

I. Situations where grinding is required

1.1 High precision requirements

If cemented carbide rods are used for precision molds, CNC cutting tools (such as milling cutters, drill bits), aerospace components, etc., where there are extremely high requirements for dimensional accuracy (such as diameter tolerance, cylindricity) and surface roughness (Ra value), grinding processing (such as centerless grinding, cylindrical grinding) must be used to meet the standards.

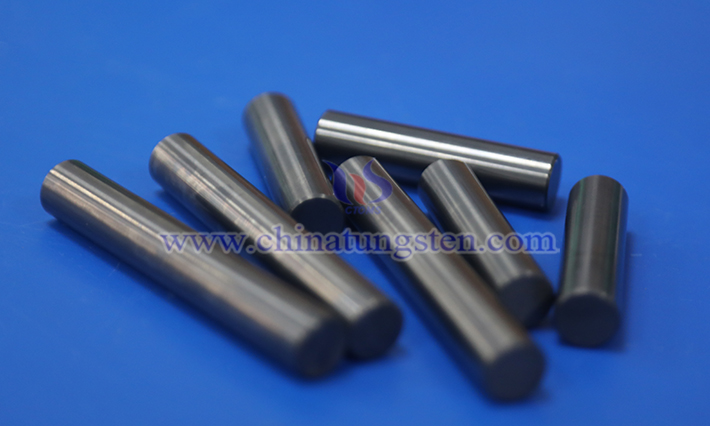

CTIA GROUP LTD Cemented Carbide Rods Pictures

1.2 Surface quality optimization

After sintering or extrusion forming, the surface of cemented carbide rods may have issues such as oxide layers, micro-cracks, burrs, or insufficient roughness. Grinding can remove defects, improve surface finish, and reduce the risk of wear or fracture in subsequent processing.

1.3 Processing of complex shapes

If the rod needs to be processed into stepped shafts, special cross-sections, or features with threads, grooves, etc., grinding (such as form grinding, thread grinding) is an efficient and high-precision forming method.

1.4 Connection with subsequent processes

When cemented carbide rods need further processing by electrical discharge machining (EDM), laser processing, or coating treatment, surface roughness must be controlled; otherwise, it will affect processing efficiency or coating adhesion. Grinding can provide a foundation for this.

II. Situations where grinding is not required

2.1 Low precision ordinary applications

If cemented carbide rods are used for ordinary stamping dies, wear-resistant parts, or scenarios with low precision requirements (such as hand tool handles), and the original surface quality already meets the usage needs, grinding is not required.

2.2 Cost and efficiency considerations

Grinding processing has high costs (equipment, consumables, man-hours). If the requirements for precision and surface quality are not high, other low-cost methods (such as sandblasting, polishing) or direct use can be adopted.

2.3 Replacement by special processes

Some cemented carbide rods are produced through ultra-precision extrusion forming or near-net-shape forming technology, with surface quality already close to grinding level, allowing direct use without additional grinding.

CTIA GROUP LTD Cemented Carbide Rods Pictures

III. Precautions for grinding processing

3.1 Process selection

Select the grinding method according to the rod size and precision requirements:

(1) Centerless grinding: suitable for high-efficiency processing of large batches and long rods.

(2) Cylindrical grinding: suitable for single-piece or small-batch, high-precision processing.

(3) Form grinding: suitable for processing complex shapes.

Parameter control: Grinding parameters (such as grinding wheel grit, feed rate, coolant) need to be optimized to avoid surface burns or cracks caused by overheating. Due to the high hardness of cemented carbide, diamond or CBN grinding wheels must be used.

Quality inspection: After grinding, it is necessary to inspect dimensional accuracy (such as with a coordinate measuring machine), surface roughness (such as with a roughness tester), and surface defects (such as with microscopic observation) to ensure compliance with requirements.