Cemented carbide rods have excellent high-temperature resistance, with their heat-resistant temperature typically reaching 800℃ to 1000℃, and some special processes or improved products can even maintain performance at higher temperatures.

I. Principle of High-Temperature Resistance of Cemented Carbide Rods

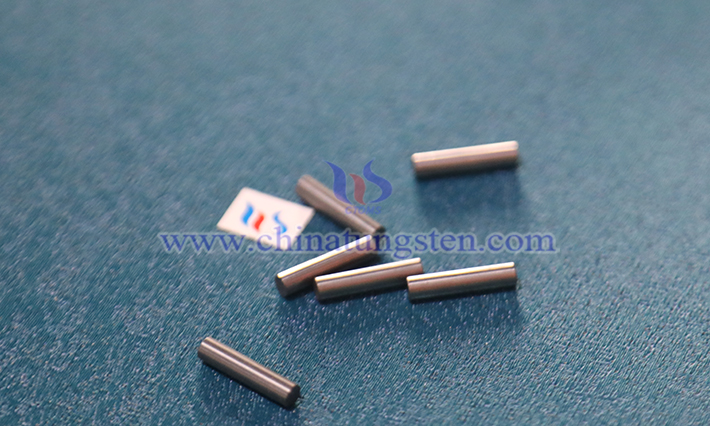

Cemented carbide rods are rod-shaped materials made with tungsten carbide as the matrix, adding cobalt, nickel, and other binders, through powder metallurgy processes. Tungsten carbide (WC) has an extremely high melting point (approximately 2870℃) and hardness, while binders such as cobalt and nickel provide good toughness and machinability. This combination allows cemented carbide rods to maintain high hardness and strength in high-temperature environments.

II. Performance of High-Temperature Resistance of Cemented Carbide Rods

2.1 High-Temperature Hardness: Cemented carbide rods can still maintain high hardness at high temperatures, which is an important manifestation of their high-temperature resistance. For example, in the temperature range of 800℃ to 1000℃, the hardness of cemented carbide rods can still reach above HRA86.5, sufficient to meet most high-temperature processing needs.

2.2 High-Temperature Strength: In addition to hardness, cemented carbide rods also have good strength at high temperatures. This means that in high-temperature environments, they can still withstand large forces and impacts without easily deforming or fracturing.

2.3 Chemical Stability: Cemented carbide rods have good corrosion resistance to general corrosive media and are not easily subjected to oxidation and corrosion. This characteristic allows them to maintain a longer service life in high-temperature environments.

III. Applications of High-Temperature Resistant Cemented Carbide Rods

3.1 Metal Cutting Tool Manufacturing: Cemented carbide rods can be used to manufacture metal cutting tools such as drill bits, end mills, and reamers. These tools can still maintain high cutting efficiency and precision in high-temperature environments, improving production efficiency.

3.2 Mold Processing: Cemented carbide rods can be used to manufacture various molds, such as stamping molds and cold extrusion molds. Their high-temperature stability and wear resistance ensure that the molds are not easily worn or deformed during long-term use.

3.3 Aerospace Field: In the aerospace field, cemented carbide rods can be used to manufacture high-temperature components, such as engine turbine disks and bases. These components need to operate for long periods in high-temperature environments, and the high-temperature performance of cemented carbide rods can meet their requirements.

3.4 Other High-Temperature Processing Fields: Cemented carbide rods can also be used in high-temperature processing processes in industries such as papermaking, packaging, printing, and non-ferrous metal processing.