The thermal conductivity of cemented carbide rods is generally poor overall, but there are differences in thermal conductivity performance among different types and compositions of cemented carbide rods.

1.Thermal Conductivity Characteristics of Cemented Carbide Rods

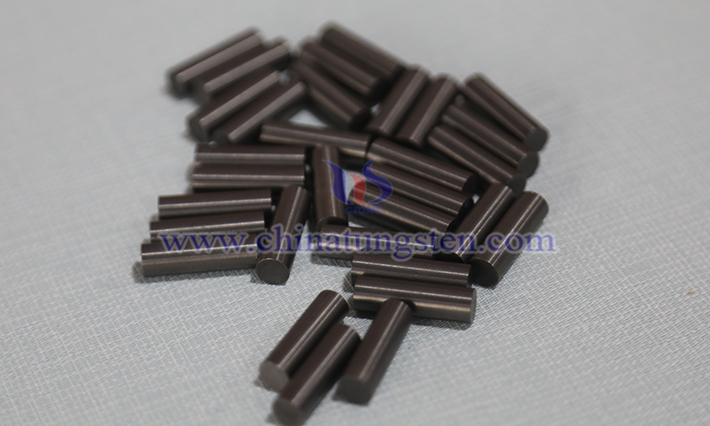

Cemented carbide rod is a rod-shaped material made with tungsten carbide (WC) as the matrix and cobalt (Co), nickel (Ni), or other binders added through powder metallurgy process. Its thermal conductivity is affected by multiple factors such as composition, grain size, and binder content. The overall thermal conductivity is relatively poor, but there are differences in thermal conductivity performance among different types and compositions of cemented carbide rods.

2.Factors Affecting the Thermal Conductivity of Cemented Carbide Rods

2.1 Composition:

WC content: WC itself is a material with relatively good thermal conductivity, so the higher the WC content in cemented carbide rods, the higher the thermal conductivity generally is. For example, in YG series cemented carbides, models with higher WC content have relatively higher thermal conductivity.

Binder content: The content of binders (such as cobalt, nickel) also has a significant impact on the thermal conductivity of cemented carbide rods. Generally, the higher the binder content, the poorer the thermal conductivity. This is because the thermal conductivity of binders is usually lower than that of hard phases such as WC.

2.2 Grain Size:

Grain refinement has basically no impact on the thermal conductivity of cemented carbide rods. For example, by comparing the thermal conductivity of YG6 with YG6X and YG6A, it can be found that grain refinement does not significantly change thermal conductivity performance.

2.3 Additives:

The addition of certain additives (such as TaC, NbC) has relatively small impact on the thermal conductivity of cemented carbide rods. These additives are mainly used to improve other properties of cemented carbide rods (such as hardness, wear resistance, etc.), while their impact on thermal conductivity is relatively limited.

3. Differences in Thermal Conductivity Among Different Types of Cemented Carbide Rods

YG series cemented carbide rods:

YG series cemented carbide rods use WC as the hard phase and cobalt as the binder. Their thermal conductivity is relatively good, but specific values vary depending on the model and composition. For example, some YG series cemented carbide rods can achieve higher thermal conductivity levels, suitable for processing scenarios requiring certain thermal conductivity.

YT series cemented carbide rods:

YT series cemented carbide rods add TiC and other hard phases on the basis of YG series to improve hardness and wear resistance. However, the addition of TiC reduces thermal conductivity. Therefore, the thermal conductivity of YT series cemented carbide rods is usually lower than that of YG series.

YW series cemented carbide rods:

YW series cemented carbide rods are a general-purpose cemented carbide, with TaC or NbC added to the composition to replace part of TiC. This alloy has high thermal hardness (>1000℃), but its thermal conductivity is between tungsten-cobalt series and tungsten-cobalt-titanium series.

4. Impact of Thermal Conductivity on Applications of Cemented Carbide Rods

Cutting processing:

In cutting processing, the better the thermal conductivity of the tool material, the faster the heat in the cutting zone is conducted away, the higher the resistance to thermal shock, and the relatively smaller the thermal wear on the tool. Therefore, for scenarios requiring high-speed cutting or processing difficult-to-machine materials, cemented carbide rods with better thermal conductivity should be selected.

Mold manufacturing:

In mold manufacturing, the thermal conductivity of cemented carbide rods has an important impact on mold cooling efficiency and processing precision. Cemented carbide rods with good thermal conductivity can conduct heat from the mold faster, thereby improving mold durability and processing precision.