Tungsten rubber glove is a radiation protection glove mainly composed of rubber substrate (such as neoprene or natural rubber latex) compounded with tungsten compounds such as tungsten oxide or tungsten carbide powder, used to shield ionizing radiation such as X-rays, γ-rays, and β-rays as well as radioactive contaminants, protecting operators' hands from radiation hazards. CTIA GROUP LTD tungsten rubber gloves typically have a structure including outer layer, inner layer, and intermediate radiation protection lining, with overall design focusing on flexibility, radiation protection, and environmental friendliness. For any tungsten rubber gloves, please contact CTIA GROUP LTD: [email protected], 0592-5129595. For more information on tungsten resin, please visit: http://www.tungsten-alloy.com/index.htm

1. Working Principle of Tungsten Rubber Gloves

The radiation protection effect of tungsten rubber gloves is mainly based on the attenuation mechanism of materials to ionizing radiation, achieving effective shielding of X-rays, γ-rays, and other radiation through high atomic number tungsten elements.

Tungsten has high atomic number and electron density. When radiation photons interact with the material, main processes include photoelectric effect, Compton scattering, and pair production. Among them, in the common energy range of medical X-rays, photoelectric effect dominates, with incident photons absorbed by inner electrons of tungsten atoms, transferring energy to the material interior, thereby greatly reducing transmitted radiation intensity. Tungsten compounds are uniformly dispersed in fine particle form in the rubber matrix, forming a continuous shielding layer, further enhancing overall attenuation capability.

The rubber substrate itself has small radiation attenuation effect but provides softness and airtightness, improving glove fit with hands, preventing ray penetration, while maintaining operational flexibility and tactile feel.

2. Performance of Tungsten Rubber Gloves

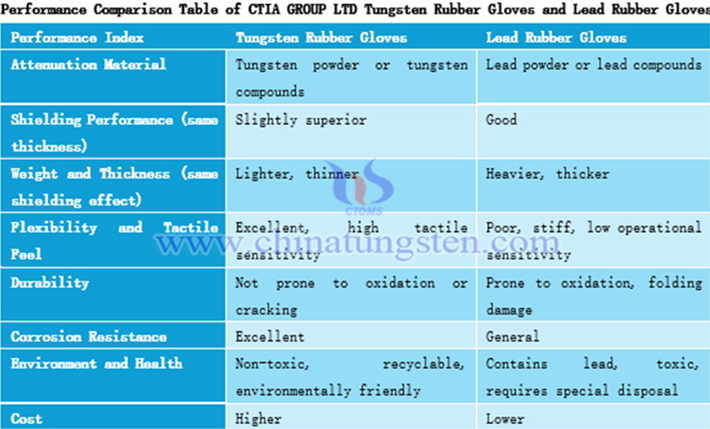

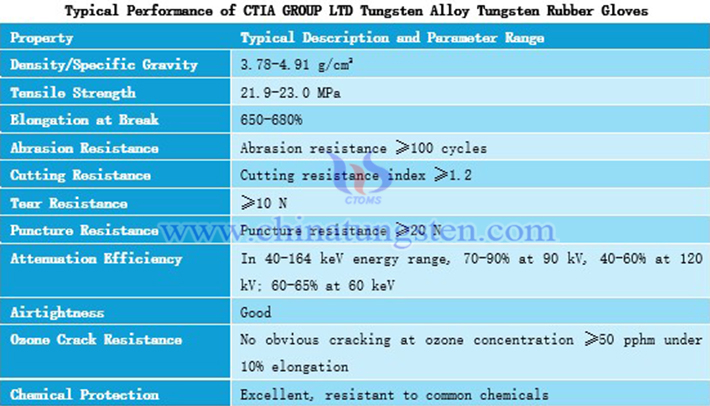

Tungsten rubber gloves, as lead-free radiation protection gloves, main features include strong radiation shielding capability, good flexibility, excellent airtightness, wear resistance, ozone aging resistance, moderate water vapor permeability, etc. In addition, their surface texture helps improve grip strength and tactile feel, suitable for medical intervention and industrial radiation environments.

3. Production Methods of Tungsten Rubber Gloves

Tungsten rubber gloves are mainly produced using dipping forming process, with steps including (1) hand mold pretreatment, (2) composite latex preparation, (3) dipping forming, (4) vulcanization curing, and (5) post-treatment.

First clean the hand-shaped mold and pre-dip in coagulant; then uniformly mix neoprene or natural rubber latex with tungsten compound powder and necessary additives through high-speed stirring to form stable composite latex; during dipping, immerse the mold in composite latex to form film; after dipping, perform leaching, beading, and preliminary drying; then enter vulcanization stage, after vulcanization complete cleaning, surface treatment, demolding, drying, and quality inspection.

4. Applications of Tungsten Rubber Gloves

Tungsten rubber gloves are mainly used in scenarios requiring hand radiation protection, suitable for long-term precision operation environments. In the medical field, commonly used in interventional surgery such as cardiovascular angiography, radiofrequency ablation, and digital subtraction angiography (DSA) operations, effectively protecting operators' hands from scattered radiation. In the industrial field, suitable for nuclear facility maintenance, radioactive material handling, and X-ray nondestructive testing. In addition, widely used in radioactive isotope experiments in scientific research laboratories and isolation operations inside glove boxes.