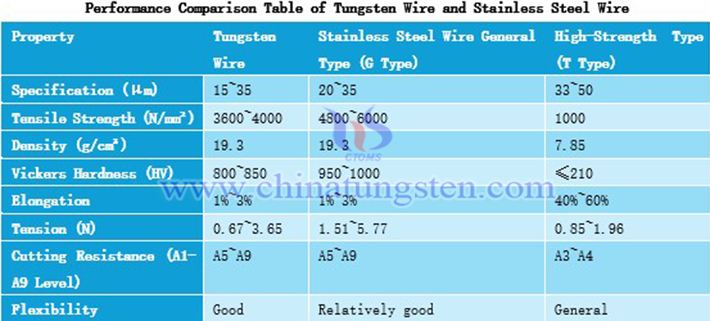

Tungsten wire woven glove is a high-performance anti-cut protective glove mainly woven from fine tungsten wire compounded with high-strength fibers such as polyethylene fiber, glass fiber, or nylon, used to protect hands from cutting, piercing, and scratching by sharp objects. Tungsten wire woven gloves typically adopt a multi-layer structure: the outer layer is a cut protection layer enhanced by tungsten wire, and the inner layer is a soft lining, achieving a balance between protection performance and wearing comfort. Compared to traditional stainless steel wire gloves, it is lighter, thinner, and more flexible while having higher protection level, widely used in high-risk operation environments. For any tungsten wire woven gloves, please contact CTIA GROUP LTD: [email protected], 0592-5129595. For more information on tungsten wire, please visit: http://www.tungsten.com.cn/index.html

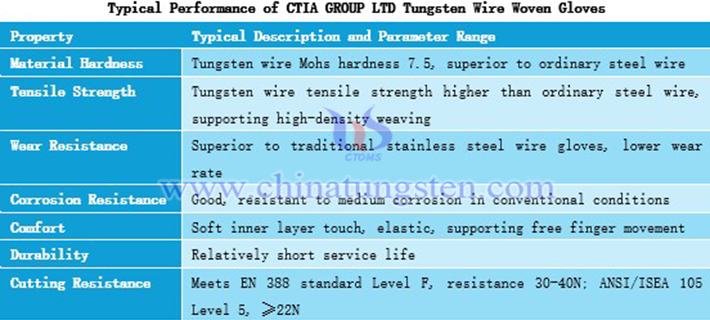

1. Performance of Tungsten Wire Woven Gloves

The main performance characteristics of tungsten wire woven gloves are strong anti-cut capability and good comfort, suitable for high-risk cutting environments, improving operation safety and efficiency. Tungsten wire has high hardness, high strength, and wear resistance, providing excellent cutting and piercing resistance for the glove, while being high-temperature and corrosion resistant. After compounding and weaving with high-performance fibers, the glove is lighter, thinner, and softer, with strong flexibility, supporting precision operations and long-term wearing.

2. Production Methods of Tungsten Wire Woven Gloves

The production of tungsten wire woven gloves mainly adopts precision knitting process. First, tungsten wire is made into fine wire through multiple drawing and surface treatment, then compounded and twisted with high-performance fibers to form main yarn and auxiliary yarn; subsequently, using special high-gauge knitting machine for weaving, adopting multi-layer structure design: outer layer mainly tungsten wire yarn, inner layer soft fiber; after weaving, perform cleaning, setting, and trimming treatment, then quality inspection and packaging for storage.

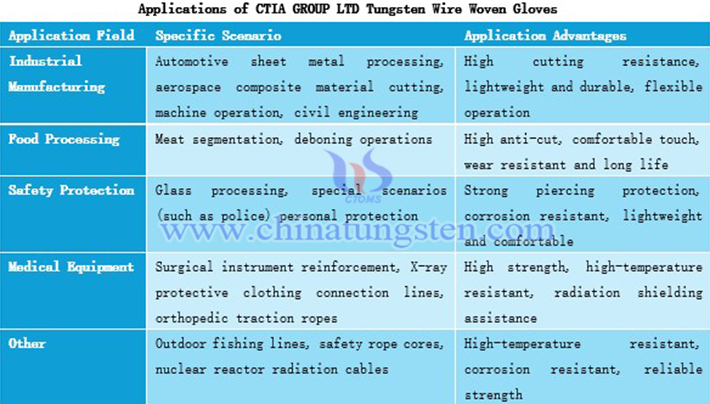

3. Applications of Tungsten Wire Woven Gloves

Tungsten wire woven gloves are mainly used in high-risk cutting and piercing environments, such as occasions requiring high protection level and operational flexibility. In industrial manufacturing field, commonly used for automotive sheet metal processing, aerospace composite material cutting, machine operation, and civil engineering, providing reliable cutting protection. In food processing, suitable for meat segmentation and deboning operations, improving operation safety. In safety protection, used for glass processing and special scenarios such as police personal protection. In addition, can be used for medical equipment reinforcement, X-ray protective clothing connection lines, and orthopedic traction ropes, as well as outdoor fishing lines, safety rope cores, and other fields.