The differences between tungsten rubber gloves and lead rubber gloves include variations in material composition, performance, production methods, and application scenarios.

1. Material Composition of Tungsten Rubber Gloves and Lead Rubber Gloves

Tungsten rubber gloves are an environmentally friendly alternative to lead rubber gloves, made from rubber or polymer substrates such as polyisoprene or silicone rubber combined with tungsten powder or tungsten compounds, providing good radiation shielding performance while avoiding lead toxicity. For any tungsten rubber gloves, please contact CTIA GROUP LTD: [email protected], 0592-5129595. For more information on tungsten resin, please visit: http://www.tungsten-alloy.com/index.htm

Lead rubber gloves are traditional radiation attenuation gloves, mainly made from natural or synthetic rubber substrates combined with lead powder or lead compounds, used to protect hands from scattered X-rays or γ-rays in medical radiation operations.

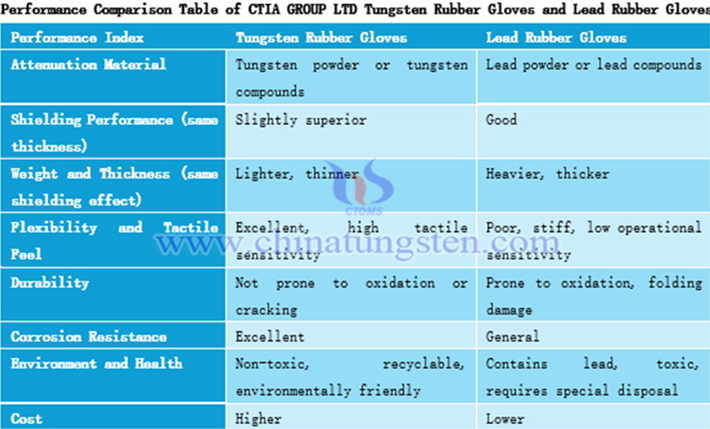

2. Performance Comparison of Tungsten Rubber Gloves and Lead Rubber Gloves

Under the premise of equivalent radiation shielding performance, tungsten rubber gloves are significantly superior to lead rubber gloves in thickness, flexibility, and tactile feel, more suitable for long-term fine operations such as interventional radiology surgery, reducing hand fatigue and improving operational precision. At the same time, CTIA GROUP LTD tungsten rubber gloves also have characteristics such as non-toxic, non-radioactive, durable, corrosion resistant, and recyclable, meeting modern environmental and health requirements. However, tungsten rubber gloves have higher cost than lead rubber gloves.

3. Production Methods of Tungsten Rubber Gloves and Lead Rubber Gloves

The production of both tungsten rubber gloves and lead rubber gloves adopts powder mixing-rubber compounding process:

Tungsten rubber gloves: First uniformly mix tungsten powder with rubber emulsion, then dip hand-shaped molds into coagulant, repeatedly dip into the composite emulsion to form uniform thin layers, and finally heat vulcanize to cure, ensuring gloves are flexible, lightweight, and have excellent radiation attenuation performance.

Lead rubber gloves: Uniformly mix lead powder with rubber such as latex, add additives, and form glove shape through dipping forming, vulcanization, or hot pressing process.

4. Applications of Tungsten Rubber Gloves and Lead Rubber Gloves

Tungsten rubber gloves and lead rubber gloves are mainly used for medical radiation protection such as interventional radiology, fluoroscopy surgery, and X-ray operations to protect operators' hands from scattered radiation. Tungsten rubber gloves are suitable for long-term fine operations such as cardiac intervention and catheter surgery, and have become the mainstream choice due to their lightweight, flexible, and good tactile feel; lead rubber gloves are suitable for general scenarios but are being replaced due to toxicity and comfort issues.