1. What Are the Application Fields of Tungsten Alloy Screws

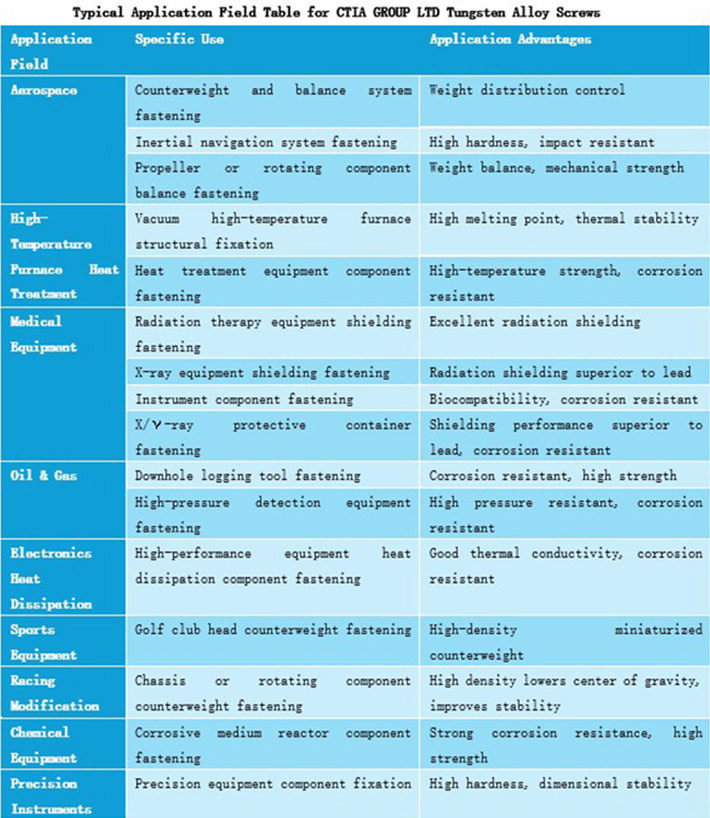

CTIA GROUP LTD tungsten alloy screws, with characteristics of high density, high strength, high temperature resistance, corrosion resistance, and excellent radiation shielding, have application fields including aerospace, high-temperature furnace heat treatment, medical equipment, and sports equipment, etc. In aerospace, tungsten alloy screws are used for counterweight balance, inertial navigation, and rotating component fastening, achieving weight optimization and mechanical stability; in the high-temperature furnace heat treatment field, used for vacuum furnace and equipment structural fixation; in medical equipment, used for radiation therapy equipment, X-ray equipment, and protective container fastening, providing biocompatibility and shielding effect superior to lead; sports equipment such as golf club head counterweight fastening, achieving miniaturized high-weight balance. For any tungsten alloy screw products, please contact CTIA GROUP LTD: [email protected], 0592-5129595. For more information on tungsten alloys, please visit: http://www.tungsten-alloy.com/index.htm

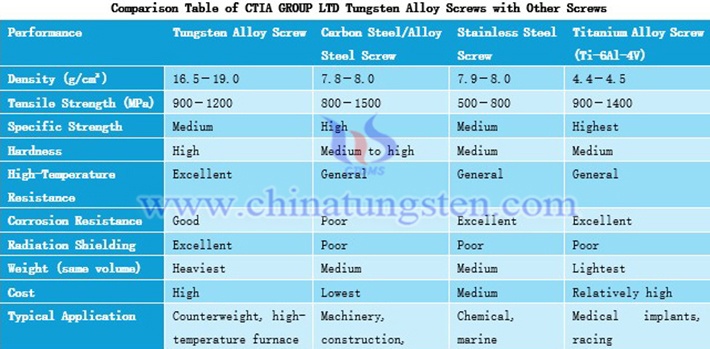

2. Comparison of Tungsten Alloy Screws with Other Screws

Compared with carbon steel/alloy steel screws, stainless steel screws, and titanium alloy screws, tungsten alloy screws have obvious advantages in counterweight, radiation shielding, high temperature (such as vacuum furnaces), and radiation protection scenarios, but are heavier, higher cost, and more brittle, not suitable for weight-sensitive or general industrial occasions. Carbon steel/alloy steel are suitable for cost-sensitive high-strength general applications; stainless steel is the cost-performance choice for corrosion resistance; titanium alloy excels in lightweight and high strength needs such as aviation and medical fields.