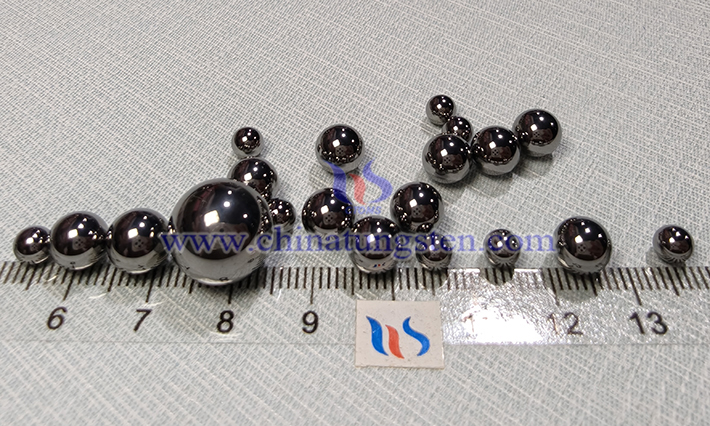

Cemented carbide balls for ball screws are spherical materials made by sintering high-hardness refractory metal carbides (such as WC, TiC) as the main component and cobalt (Co), nickel (Ni), or molybdenum (Mo) as a binder through powder metallurgy. They possess high hardness, wear resistance, corrosion resistance, and bending resistance, and can replace steel balls in ball screws to achieve high-precision, long-life transmission and support.

1. Performance Advantages of Cemented Carbide Balls for Ball Screws

1.1 High Hardness: Hardness ≥ 90.5 HRA (Rockwell hardness), far exceeding that of ordinary steel balls, capable of withstanding high loads and high-frequency impacts.

1.2 Wear Resistance: Wear resistance is dozens of times that of steel balls, significantly extending the service life of ball screws and reducing maintenance frequency.

1.3 Corrosion Resistance: Resistant to oxidation in humid, acidic, or salt spray environments, suitable for harsh environments such as chemical and marine applications.

1.4 Bending Resistance: High elastic modulus and fatigue resistance ensure deformation stability during high-speed operation.

1.5 High Temperature Adaptability: Stable operation in environments above 400℃; some grades (such as YG8) maintain high hardness even at 1000℃.

2. Application Scenarios of Cemented Carbide Balls for Ball Screws

2.1 Transmission and Support Core: As the rolling element of the ball screw, cemented carbide balls roll between the nut and the screw through a circulation system, converting rotational motion into linear motion for high-precision positioning. Their high hardness and wear resistance ensure minimal raceway wear during long-term operation, maintaining transmission efficiency and repeatability.

2.2 High-Load and High-Speed Scenarios: In CNC machine tools, industrial robots, and other equipment, cemented carbide balls can withstand high axial loads (such as heavy-duty cutting) and high-speed operation, preventing the decrease in precision caused by thermal expansion or wear of steel balls.

2.3 Harsh Environmental Adaptability: In corrosive environments such as chemical and food processing, the corrosion resistance of cemented carbide balls prevents failure caused by media erosion. In high-temperature forging and metallurgical applications, its high-temperature resistance ensures stable operation of equipment under extreme temperatures.