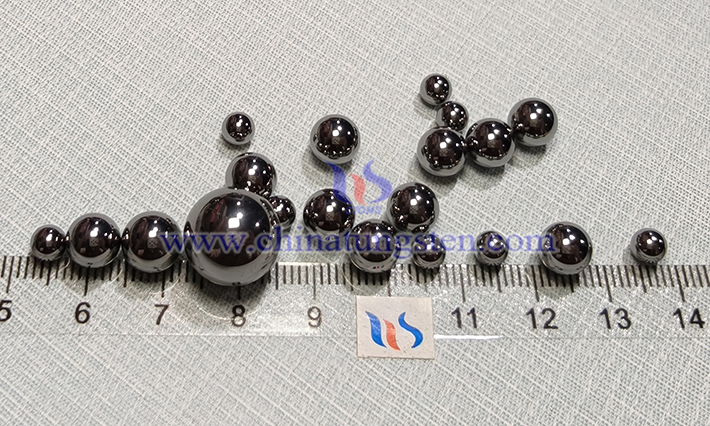

Cemented carbide balls, commonly known as tungsten carbide balls, are composite materials made by sintering hard metal powders such as tungsten carbide with binders such as cobalt using powder metallurgy technology under high temperature and pressure. They possess extremely high hardness, wear resistance, and corrosion resistance.

Punching balls are specialized tool balls primarily used in punching processes in machining. Their core purpose is to create holes in metals or other materials through extrusion or punching, often used for surface finishing of parts.

During the punching process, the punching ball typically acts as a punch or extrusion tool, utilizing its high hardness and high precision characteristics to perform localized plastic deformation of the material, thereby achieving efficient and precise hole processing. Now of punching, the ball head contacts the metal material being processed at a single point, gradually reducing the contact area to a smaller area as it moves downwards. This process improves the dimensional accuracy and surface hardness of machined surfaces, reduces burrs and deformation at punched edges, and improves roughness, making it suitable for mass production to enhance efficiency. Furthermore, the spherical punch distributes force more evenly, and wear is more uniform around its edges, significantly extending its service life.

Because punching balls must withstand significant pressure, they are often made of high-hardness materials to ensure durability and processing quality. In continuous, high-speed automated production, the lifespan of cemented carbide punching balls can be tens or even hundreds of times longer than that of ordinary alloy steel punches. Although the initial purchase cost is higher, the cost per hole and downtime due to tool changes are significantly reduced.

Typical applications of cemented carbide punching balls include precision punching and drawing, and extrusion punching, commonly found in machinery manufacturing, instrumentation, and aerospace industries. For example, it is used in automotive parts production lines to punch various holes in brake discs and suspension components; in elevator manufacturing, it is used to precision-stamp anti-slip holes on step plates; in the power industry, it is used for high-density punching of transformer heat sinks; and in the photovoltaic and building sectors, it is used for processing mounting holes for solar panels and metal curtain wall panels. It can be found in any situation requiring the punching of high-quality round holes in thin to medium-thick metal plates under high-volume, high-strength conditions.