WC-TiC cemented carbide valve balls are made primarily of tungsten carbide (WC) and titanium carbide (TiC), sintered with cobalt (Co) and other metal binders. They feature high hardness, wear resistance, corrosion resistance, high temperature and pressure resistance, reliable sealing, rapid opening and closing, impact resistance, and long service life, making them widely applicable in harsh industrial environments such as oil drilling, deep-sea drilling, and oil and gas transportation.

Key features of WC-TiC cemented carbide valve balls:

1. High Hardness and Wear Resistance: WC-TiC cemented carbide valve balls possess extremely high hardness, typically exceeding HRA 90. This high hardness gives them excellent wear resistance, allowing them to operate for extended periods in high-load, high-friction environments without significant wear, thus extending the valve ball's service life.

2. Excellent Corrosion Resistance: Cemented carbide materials possess excellent chemical stability, resisting the erosion of most corrosive media. This makes WC-TiC cemented carbide valve balls suitable for pipeline systems transporting corrosive substances, such as sulfur-containing oil and gas wells and chemical pipelines.

3. High Temperature and High-Pressure Resistance: WC-TiC cemented carbide valve balls maintain stable performance under high temperature and high-pressure environments. The material's high melting point and good thermal stability make it suitable for extreme conditions such as deep wells and high-temperature oil reservoirs, ensuring the valve ball continues to function normally under these conditions.

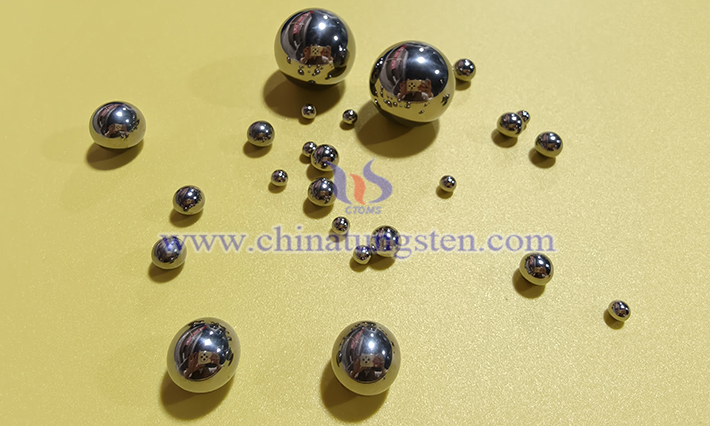

4. Good Sealing Performance: The sealing performance between the valve ball and seat directly affects the overall performance of the valve. WC-TiC cemented carbide valve balls have precise sphericity and a smooth surface, achieving excellent sealing and preventing media leakage.

5. Rapid Opening and Closing, Flexible Operation: Cemented carbide valve balls open and close through rotation, resulting in short opening and closing times and flexible operation. This rapid opening and closing characteristic allow the valve to respond promptly to system needs, improving work efficiency.

6. Excellent Impact Resistance: WC-TiC cemented carbide valve balls possess high impact resistance, capable of withstanding impact loads in pipeline systems, and are less prone to cracking or damage, ensuring safe valve operation.

7. Long Service Life and Low Maintenance Costs: Due to the excellent wear resistance and corrosion resistance of WC-TiC cemented carbide valve balls, their service life is far longer than that of valve balls made of traditional materials. This reduces the frequency of valve replacement and maintenance costs, improving economic efficiency.

8. Wide Range of Applications: WC-TiC cemented carbide valve balls are suitable for various harsh industrial environments, including oil drilling, deep-sea drilling, oil and gas transportation, and chemical production. Their superior performance makes them an ideal choice for valve components in these fields.