Tungsten copper electrode is a pseudo-alloy material composed of tungsten and copper, prepared through copper infiltration process. It uses tungsten as the skeleton to provide high melting point and wear resistance, and copper as the filling phase to impart excellent electrical and thermal conductivity performance. CTIA GROUP LTD tungsten copper electrodes are mainly applied in fields such as electrical processing, welding, and high-temperature components. In EDM, they serve as precision electrodes for mold manufacturing and difficult-to-machine material forming; in resistance welding, they are used as welding tips or contacts for spot welding, projection welding, and seam welding; in high-voltage electrical switches and vacuum discharge tubes, they serve as arc ablation-resistant contacts. For any Tungsten copper electrode products, please contact CTIA GROUP LTD: [email protected], 0592-5129595. For more information on tungsten copper electrodes, please visit: http://www.tungsten-copper.com/index.html

1. Performance of Tungsten Copper Electrodes

The basic performance of tungsten copper electrodes benefits from tungsten’s high melting point, ablation resistance, and hardness, as well as copper’s excellent electrical and thermal conductivity, achieving a balance of electrical, thermal, and mechanical properties through compounding, performing excellently in high-temperature, high-current, and arc environments, capable of reducing electrode loss and extending service life, suitable for precision processing and high-load conditions.

It is worth noting that the performance parameters of tungsten copper electrodes are not fixed and are affected by material composition ratios. Generally, higher copper content results in better electrical and thermal conductivity but weaker high-temperature and ablation resistance; higher tungsten content leads to superior hardness, arc ablation resistance, and high-temperature performance but weaker electrical and thermal conductivity. Therefore, in practical applications, the composition ratio needs to be optimized according to working condition requirements to achieve the best comprehensive performance.

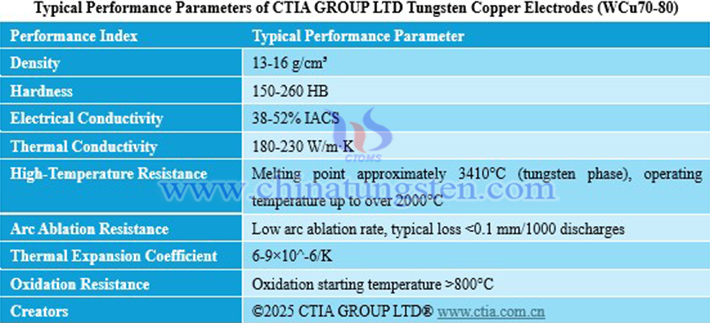

Typical Performance Parameters of CTIA GROUP LTD tungsten copper electrode Products

WCu70 (70% tungsten 30% copper): electrical conductivity approximately 48-52% IACS, thermal conductivity approximately 210-230 W/m·K, hardness approximately 180-200 HB, thermal expansion coefficient approximately 8-9×10^-6/K, suitable for occasions with higher electrical and thermal conductivity requirements such as resistance welding.

WCu80 (80% tungsten 20% copper): electrical conductivity approximately 40-45% IACS, thermal conductivity approximately 190-200 W/m·K, hardness approximately 220-240 HB, thermal expansion coefficient approximately 7×10^-6/K, stronger ablation resistance, suitable for precision EDM and high-corrosion environments such as high-voltage discharge tubes.

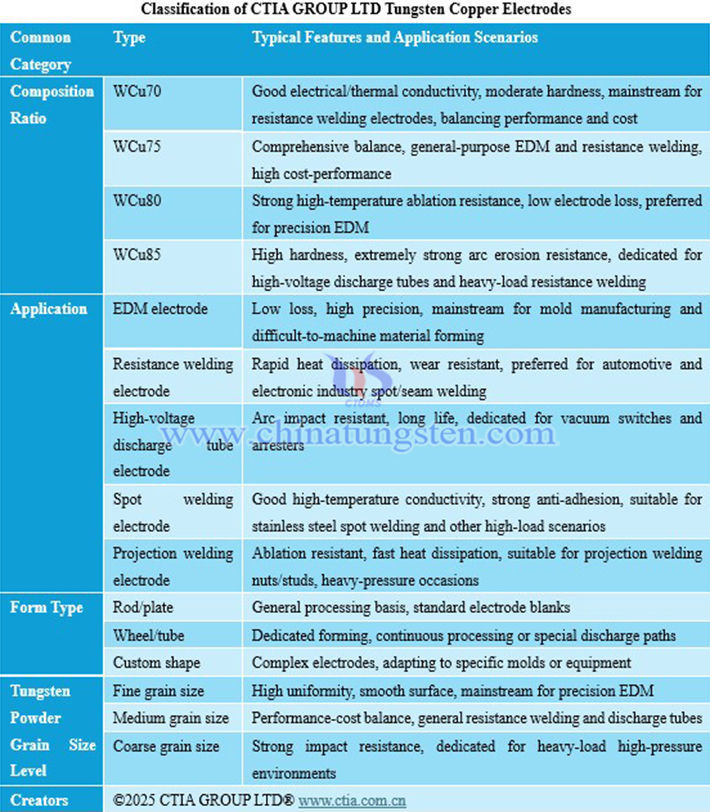

2. Classification of tungsten copper electrodes

The classification of CTIA GROUP LTD tungsten copper electrodes mainly revolves around composition ratio, application field, form type, and grain size level to facilitate selection according to working conditions. Composition ratio is the core classification: WCu70-75 leans toward balance of electrical/thermal conductivity and cost, suitable for medium-load scenarios such as resistance welding; WCu80-85 emphasizes high-temperature and ablation resistance, suitable for precision EDM and high-voltage discharge tubes, reducing loss and extending life. Application field classification highlights specialization, such as EDM requiring low loss and high precision, resistance welding focusing on heat dissipation and wear resistance. Form type adapts to processing needs, with rods and plates as basics, custom shapes for complex applications. Tungsten powder grain size level affects microscopic performance: fine grain size improves uniformity and surface quality, medium-coarse grain size balances strength and economy.

3. Production Methods of Tungsten Copper Electrodes

The production of Tungsten copper electrodes is key to achieving uniform compounding of tungsten and copper, two metals that are mutually insoluble (high tungsten melting point, low copper melting point, cannot be produced by melting method). The mainstream process is powder metallurgy, supplemented by infiltration method, spark plasma sintering (SPS), and other technologies. Different processes are suitable for different grades and performance requirements of Tungsten copper electrodes.

(1) Powder Metallurgy Infiltration Method (also known as Copper Infiltration Method)

This method has mature process, controllable cost, and is suitable for mass production. It is currently the most widely used preparation process in industry, suitable for conventional Tungsten copper electrodes with copper content 20%–50%. Its essence is to first form a solid porous tungsten skeleton, then use copper liquid capillary penetration to achieve densification.

Process flow: First select high-purity tungsten powder and copper powder, weigh them in a certain proportion, use ball milling or V-type mixer with process control agent for thorough mixing and drying granulation to improve powder flowability. Then press the mixed powder into blanks through cold isostatic pressing. The blanks are first low-temperature pre-sintered under hydrogen or vacuum protection atmosphere to remove residual moisture and volatiles, then heated to a temperature where tungsten particles can bond mutually but still maintain connected pores for tungsten skeleton sintering. Next, place the sintered tungsten skeleton together with copper blocks in a graphite boat or crucible, heat under hydrogen protection to above copper melting point, allowing molten copper liquid to infiltrate tungsten skeleton pores by capillary force. After infiltration is completed, machine or chemically clean the infiltrated blank surface to remove excess copper layer, obtaining finished Tungsten copper electrode with ideal shape dimensions and smooth surface.

(2) Spark Plasma Sintering Method (SPS)

This method has low sintering temperature and short holding time, effectively inhibiting grain growth to obtain fine-grained and dense structure, making electrodes superior in arc ablation resistance and conductivity, but expensive equipment, suitable for high-performance, small-batch, or modified Tungsten copper electrodes with third components (such as Cr, Zr).

Process flow: Load uniformly mixed tungsten-copper powder into graphite mold, apply axial pressure and pulse high current simultaneously in vacuum or protection atmosphere, relying on instantaneous Joule heat and discharge plasma to activate powder surface, completing sintering densification in short time without separate infiltration step.

(3) High Copper Content Impregnation Method

For Tungsten copper electrodes with copper content exceeding 50%, as tungsten skeleton porosity is too high and difficult to form, reverse impregnation process is often used.

Process flow: First prepare porous copper matrix or copper blank, then fill tungsten powder with temporary binder into paste to fill or impregnate copper matrix pores, subsequently low-temperature volatilize binder and secondary high-temperature sintering to firmly bond tungsten particles with copper matrix.

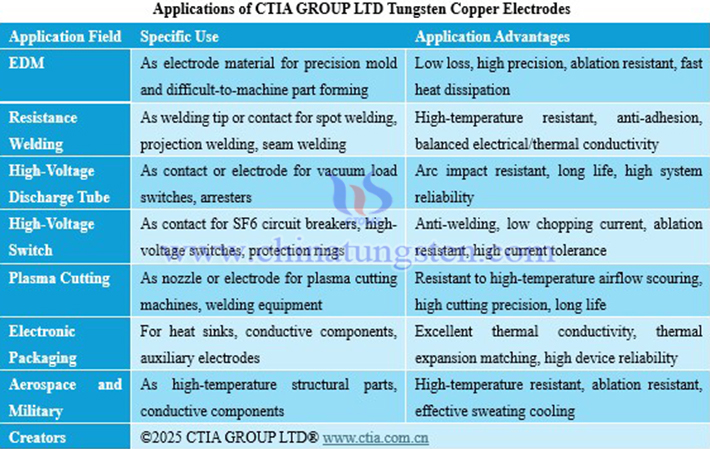

4. Applications of Tungsten copper electrodes

CTIA GROUP LTD Tungsten copper electrodes, with excellent characteristics such as high-temperature resistance, ablation resistance, and balanced electrical/thermal conductivity, have become the mainstream choice in electrical processing, welding, and high-voltage electrical fields, significantly improving processing precision, equipment life, and system stability; in electronic packaging and extreme environment applications, they leverage superior thermal management and heat resistance advantages, promoting development of precision manufacturing and high-end equipment.