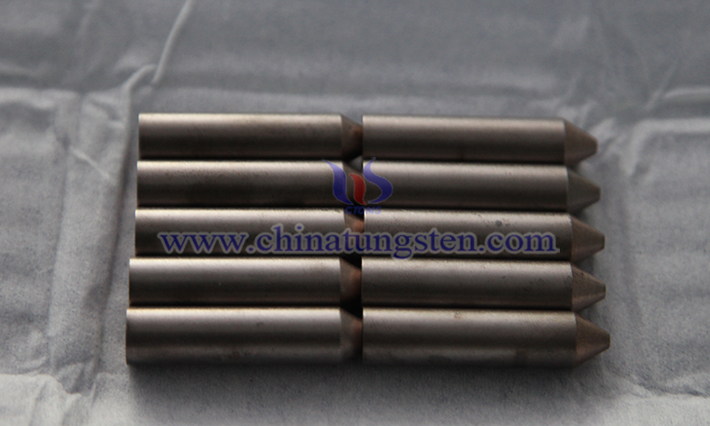

CTIA GROUP LTD tungsten copper electrode is a composite metal material with high-purity tungsten powder and copper powder as main components, manufactured through isostatic pressing, high-temperature sintering and other processes, with tungsten particles serving as the skeleton. Molybdenum-copper electrode is similarly a composite material, but with molybdenum particles replacing tungsten as the skeleton and copper phase forming the conductive network. This similar composite design allows both to have good electrical and thermal conductivity and arc ablation resistance, capable of rapidly conducting heat and current through the copper phase while relying on the refractory phase to maintain high-temperature shape stability, performing excellently in electrical contact and electrical processing fields.

In terms of performance, the differences between the two mainly stem from the comparison of physical properties of the refractory phases. Tungsten copper electrodes have a higher melting point tungsten skeleton and stronger hardness, with outstanding skeleton stability under arc high temperature; after copper phase melting, it is constrained by tungsten particles, resulting in fine and uniform ablation morphology, suitable for occasions requiring higher ablation resistance and high-temperature resistance. Molybdenum-copper electrodes have a slightly lower molybdenum phase melting point but lighter density, with thermal expansion coefficient closer to some semiconductor materials, good synergy with copper phase thermal conductivity, performing excellently in heat diffusion and temperature gradient control. The overall hardness of molybdenum-copper electrodes is slightly lower than tungsten-copper, but processing deformation resistance is smaller, and surface quality is easier to maintain.

From the process perspective, the differences between tungsten copper electrodes and molybdenum-copper electrodes are reflected in machinability. Tungsten copper electrodes have higher hardness tungsten phase, requiring auxiliary heat treatment during processing, but the copper phase gives it certain cold working ability, capable of preparing complex shapes, suitable for mass production. Molybdenum-copper electrodes have relatively soft molybdenum phase, better overall machinability, smooth cold rolling and stamping, suitable for precision dimension control.

In applications, CTIA GROUP LTD tungsten copper electrodes are often used in medium-high voltage switches, EDM electrodes, and resistance welding electrodes, emphasizing ablation resistance and high-temperature stability; molybdenum-copper electrodes are more common in medium-low voltage contactors, heat dissipation substrates, and electronic packaging transition layers, highlighting thermal matching and lightweight requirements.