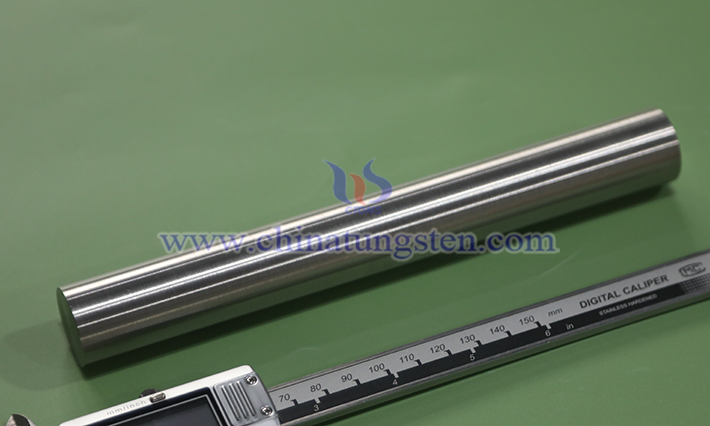

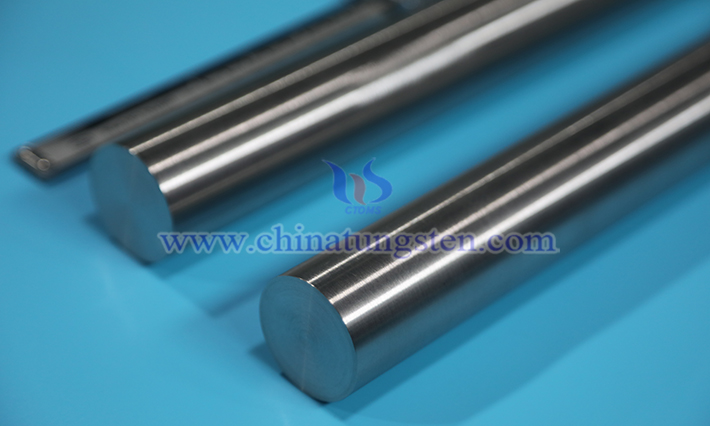

Tungsten-nickel-copper alloy rods are ternary high-density composite material rod-shaped components with tungsten as the main phase and nickel and copper as the binder phases, belonging to the category of non-magnetic heavy alloy systems, widely applied in medical imaging, aerospace inertial navigation and precision counterweight fields.

From the perspective of material composition and microstructure, the tungsten content in tungsten-nickel-copper alloy rods usually dominates, forming a continuous or quasi-continuous hard skeleton, while the nickel-copper phase fills the gaps between tungsten particles through a liquid-phase sintering mechanism, forming a network-like binder structure. The ratio of nickel to copper can be adjusted according to specific needs, usually with nickel content higher than copper to enhance binder strength, while copper optimizes thermal conductivity and corrosion resistance. Microscopically, the tungsten phase provides high-modulus support, the nickel-copper phase endows the alloy with overall plastic coordination and non-magnetic response, and the microstructure presents typical tungsten sphere-binder phase dual-phase characteristics, with clean grain boundaries and strong interface bonding.

In terms of performance, the outstanding characteristics of tungsten-nickel-copper alloy rods stem from the synergistic effect of the ternary components. Tungsten's high atomic mass and dense packing endow the alloy rods with higher density, achieving large weight in limited space, far exceeding traditional steel or lead-based materials. The non-ferromagnetic nature of the nickel-copper binder phase ensures that the alloy rods' magnetic permeability is close to vacuum value, eliminating ferromagnetic interference and meeting the stringent requirements of magnetic field-sensitive environments. At the same time, nickel's solid-solution strengthening and copper's thermal conductivity contribution enable the alloy rods to have excellent mechanical properties and thermal management capabilities: high tensile strength, moderate impact toughness, moderate and stable thermal conductivity, maintaining structural integrity under dynamic loads and temperature fluctuations.

In the field of medical imaging and diagnostic equipment, tungsten-nickel-copper alloy rods are mainly used in counterweight and positioning components of magnetic resonance imaging (MRI) systems. Their non-magnetic characteristics ensure that the strong magnetic field uniformity is not disturbed, avoiding imaging artifacts and diagnostic errors, while high density achieves center-of-gravity adjustment in smaller space, improving equipment stability and scanning accuracy.

Aerospace and inertial navigation are another key application field for tungsten-nickel-copper alloy rods. In satellite attitude control systems or aircraft inertial measurement units, they are made into gyro rotors or balance blocks, utilizing high density to achieve high moment of inertia, while non-magnetic characteristics avoid interference with magnetic-sensitive sensors or geomagnetic navigation.

The field of precision counterweight and vibration control further expands the application range of tungsten-nickel-copper alloy rods. In high-precision balances or analytical instruments, they are processed into micro-weights or calibration blocks, utilizing high density and non-magnetic properties to achieve interference-free traceability of standard masses. In high-speed rotating machinery such as centrifuges or turbomolecular pumps, balance rings or damping parts made of this material can effectively suppress unbalanced forces in narrow spaces, reducing vibration noise and bearing wear.