Tungsten crucibles play an important role in high-temperature metallurgy, crystal growth, vacuum smelting and other fields, and have long been known for their excellent high temperature resistance and good chemical stability.

However, with the increasing complexity of the application environment, more and more users have begun to pay attention to its wear resistance. Abrasion resistance, as an index to measure the ability of materials to resist surface damage under mechanical actions such as friction, impact, and grinding, is a performance index that cannot be ignored for W crucibles that are frequently loaded and unloaded, smelted many times, or need to move in the mechanical system.

First of all, from the perspective of material nature, tungsten, as a metal with a high melting point, has extremely high hardness. At room temperature, the Vickers hardness of pure tungsten can reach 350~500 HV, and its hardness can be further improved after appropriate alloy treatment or grain refinement. This high hardness provides tungsten crucibles with a certain resistance to scratches during use. For example, during loading and unloading raw materials, moving crucibles, or cleaning residues, surfaces are less susceptible to abrasion by metal tools or particles. In addition, compared with common crucible materials such as graphite and ceramics, tungsten's metallic bond structure makes it less susceptible to fracture due to microcrack propagation, thus indirectly enhancing the wear life.

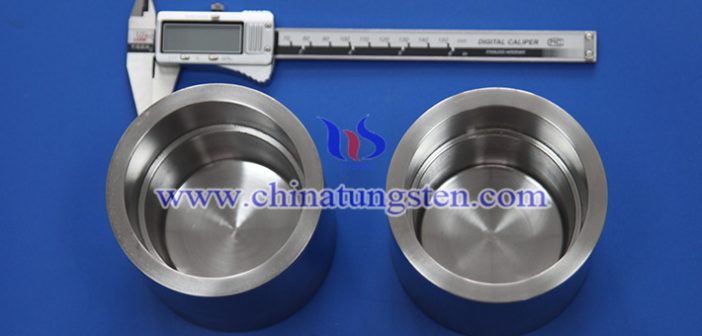

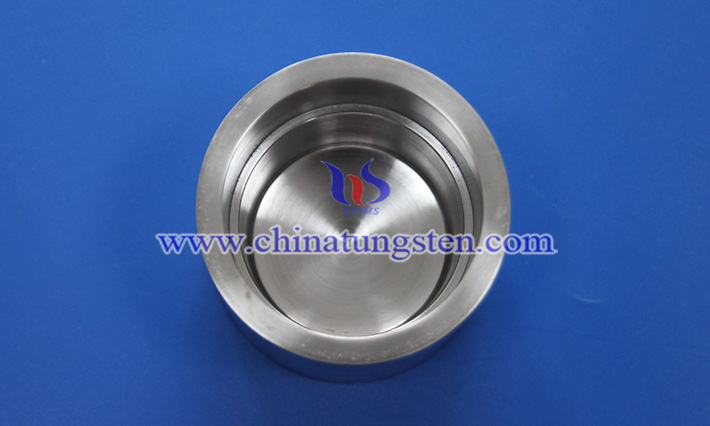

Secondly, the wear-resistant performance of tungsten crucible is closely related to its processing technology. Crucibles that are usually formed by isostatic pressure and machined after forging have a dense grain structure and excellent surface quality, so they have better wear resistance. However, if it is prepared by sintering or casting process, there may be porosity or brittle inclusions, which are easy to fail prematurely under wear stress. Some high-end manufacturers will also improve the surface finish of the crucible through surface polishing and electrolytic treatment, reduce the coefficient of friction, so as to further extend its service life.

In addition, the working environment also has an impact on the wear resistance of the W crucible. When used in a high vacuum or inert atmosphere, its surface is not easy to oxidize, and can maintain structural stability for a long time. However, in the presence of oxygen or water vapor in a high-temperature environment, brittle layers such as tungsten oxide (WO?) may form on the surface of tungsten, which can easily peel off in repeated thermal cycles and mechanical contact, thereby reducing the overall wear resistance. Therefore, for wear-sensitive applications, tungsten crucibles with an anti-oxidation protective coating or operating in a controlled atmosphere should be preferred.

Finally, it should be noted that although W crucibles have excellent wear resistance, they are not designed for high-frequency mechanical friction. If there is strong mechanical friction in the application scenario, such as powder stirring, frequent rotation or particle impact, it is recommended to use it with other wear-resistant materials, or consider composite materials such as tungsten molybdenum alloy and tungsten carbide coating to improve the overall wear resistance.