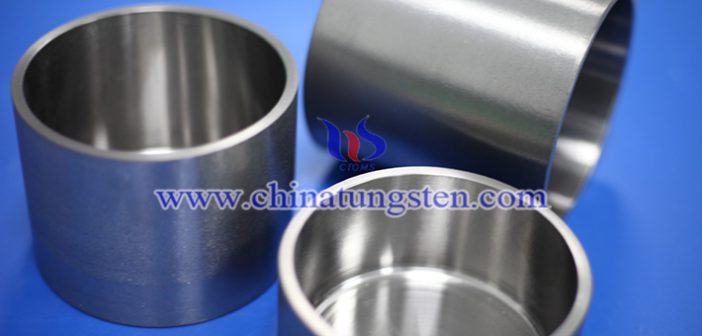

Single crystal growth is a key process for the preparation of high-purity and structurally perfect crystals, which are widely used in semiconductors, photovoltaics, lasers and optical devices, such as the preparation of silicon single crystals, sapphire single crystals and gallium arsenide single crystals. As a high-temperature container, tungsten crucibles are able to withstand extreme process conditions, ensuring stable and high quality crystal growth.

Role in the growth of single crystals

Single crystal growth is typically done using processes such as the Czochralski method, heat exchange method, or Kyropoulos method, which involves precise control of high-temperature melts (e.g., silicon, alumina), often at temperatures between 1500°C and 2200°C. With a high melting point of 3422°C, the W crucible is able to maintain structural integrity without melting or deformation at these high temperatures. For example, in the growth of sapphire single crystals, the crucible is used as a container for the alumina melt, which needs to be operated at a temperature of about 2050°C for a long time, and its high temperature resistance ensures the stability of the process.

In the semiconductor industry, crucibles are used for the growth of silicon single crystals and compound semiconductors such as gallium arsenide, indium phosphide. The low vapor pressure and chemical inertness of the crucible effectively reduce impurity contamination and ensure the electrical properties of the crystal. In addition, crucibles are also used in the preparation of laser crystals such as yttrium aluminum garnet, whose uniform temperature distribution helps to form single crystal structures with few defects.

Performance Benefits

The wide application of tungsten crucibles in the growth of single crystals is due to its many excellent properties. First, its ultra-high melting point and high temperature resistance allow it to withstand the extreme temperatures found in a single crystal growth furnace and avoid vessel failure. Secondly, the W crucible has excellent chemical stability and is able to resist corrosion by high-temperature melts. For example, alumina melts have certain chemical activity at high temperatures, while W crucibles can effectively avoid reactions with the melt and maintain crystal purity.

The thermal shock stability of tungsten crucibles is another key advantage. The single crystal growth process involves multiple thermal cycles, and the crucible is subjected to rapid heating and cooling from room temperature to over 2000°C. Tungsten's low coefficient of thermal expansion (about 4.5×10??/K) and high thermal conductivity (about 173 W/m·K) make it less prone to cracking under thermal shock, and extend its service life. In addition, the high mechanical strength of the W crucible ensures that it can resist stresses during melt flow or crystal lifting at high temperatures, maintaining structural stability.

The high thermal conductivity of tungsten crucibles also contributes to the formation of a uniform temperature field, which is essential for single crystal growth. Uniform temperature distribution reduces thermal convection and defects in the melt and improves crystal quality. For example, in sapphire growth, the thermal conductivity of the crucible helps to control the shape of the crystal-melt interface and optimize the direction of crystal growth.