As a high-melting-point, durable material, cut-resistant tungsten wire is widely used in photovoltaic silicon wafer cutting, electrical discharge machining (EDM), precision mechanical processing, and nuclear shielding. Based on its material properties, production processes, and practical applications, its environmental benefits are highlighted in the following aspects:

1. Reducing Resource Consumption-Related Pollution

As a substitute for traditional high-carbon steel wire, tungsten wire offers a lifespan 10–20 times longer than comparable materials (e.g., EDM cutting wires can endure over 40 cycles), significantly reducing the frequency of metal consumable replacements. In the machining industry, for instance, tungsten wire generates only 5%–8% of the metal waste produced by high-carbon steel for the same output. Additionally, its high cutting precision minimizes raw material loss.

2. Avoiding Risks from Toxic Substances

Tungsten-based alloys replace hazardous materials across multiple fields:

Radiation shielding: Tungsten-nickel-copper alloys replace lead-containing protective materials (e.g., shielding layers in medical CT equipment), eliminating lead pollution while improving shielding efficiency by 70%.

Electronics industry: Substitutes cadmium-containing electrode materials, avoiding heavy metal plating pollution.

Military applications: Serves as an eco-friendly alternative to depleted uranium alloys, addressing radioactive residue concerns.

3. Enhanced Circular Economy Features

Recyclability: Waste tungsten wire can be converted into recycled tungsten powder through high-temperature smelting (recovery rate >95%), saving 30% energy compared to traditional metallurgical processes.

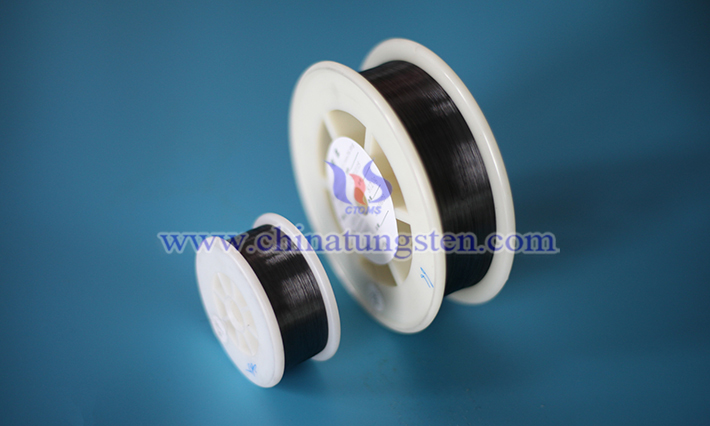

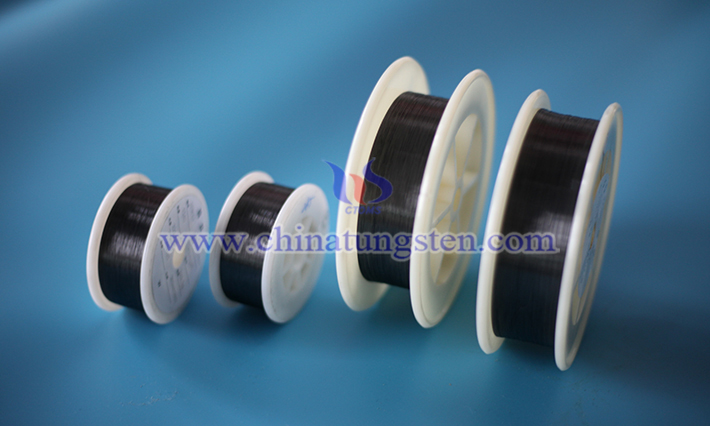

Strategic resource value: While China holds the world’s largest tungsten reserves, primary product exports dominate, with traditional applications concentrated in low-end industries. High-value-added tungsten wire products (e.g., ultra-fine wires <0.03mm in diameter) improve resource utilization efficiency, aligning with sustainable development strategies. 4. Process Compatibility Advantages Tungsten wire production processes are compatible with high-carbon steel wire equipment, minimizing resource waste from technological upgrades due to low conversion costs. 5. Potential Environmental Risks and Mitigation Despite its environmental strengths, improper disposal of waste tungsten wire poses risks. If mishandled, it may release harmful substances (e.g., tungsten compounds), polluting soil and water, and even cause fire or puncture hazards. Thus, robust recycling systems must be established to enable safe treatment (e.g., high-temperature smelting), alongside strengthened protective measures for workers.